The Kawaoka A2 interlock system, offered by VCR, represents a significant advancement in cleanroom access control technology.

This article delves into its features, functionalities, and applications, providing a comprehensive understanding for cleanroom professionals.

I. Understanding Interlocks and the Kawaoka A2 Distinction

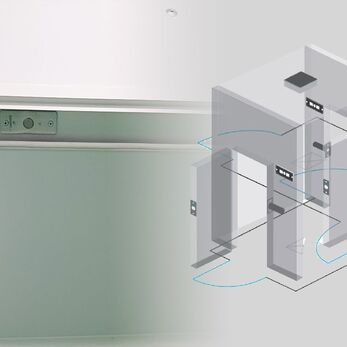

Cleanroom interlocks are electronic devices that synchronize the opening and closing of doors within an airlock, minimizing the risk of contamination.

See more: What is cleanroom interlock

The Kawaoka A2 interlock sets itself apart with its smart functionalities:

- Adjustable Time Delays: Users can customize the time interval between opening and closing doors, ensuring optimal airlock efficiency for various cleanroom environments.

- Audio and Visual Alerts: The system utilizes both audible (sound) and visual (LED panel indicators) alerts to inform personnel about door status and potential safety concerns.

II. System Components and Construction

The Kawaoka A2 system comprises three core elements:

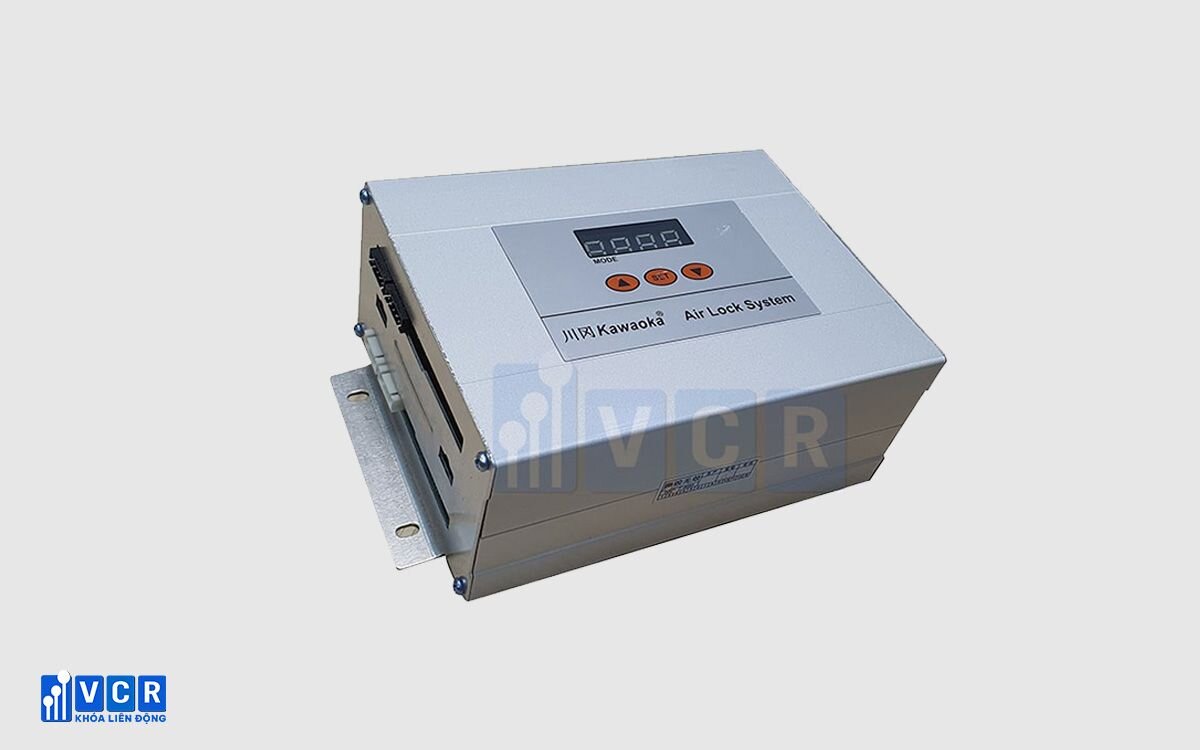

1. Control Box:

- Constructed from durable aluminum for enhanced longevity.

- Features an active control button in the center for manual operation.

- Includes a power outlet on the right and jacks for connecting locks and LED panels on the left.

See more: Different Categories Of Cleanroom Interlock

2. Electric lock latch:

- Stainless steel lock pins ensure corrosion resistance and operational reliability.

- Lock sheets are constructed from a combination of stainless steel and hard plastic for strength and durability.

See more: Why Cleanrooms Depend on Door Interlock Systems

3. LED Panels:

- The number of panels varies based on the interlock configuration (4 panels for 2-door, 6 panels for 3-door).

- Each panel displays four key indicators:

- Closing and opening time settings

- Door open/close status

- Emergency button for overriding the interlock and enabling manual door opening in case of emergencies.

See more: What is Cleanroom Airlock according to gmp

III. Operational Dynamics of the 2-Door Kawaoka A2 Interlock

Opening door 1 triggers the following sequence:

- Door 1's LED panel displays green, indicating the open state.

- Door 2's LED panel displays red, signifying that it is locked and cannot be opened.

- An adjustable delay (around 6 seconds) occurs before the system emits an audible warning to remind personnel to close door 1.

- After another 6 seconds, door 2 becomes eligible for opening, with its LED panel turning green. Conversely, door 1's LED panel turns red, preventing accidental re-opening.

See more: 2-Door Cleanroom Interlock Systems

IV. Kawaoka A2 Interlock Variations

Kawaoka A2 interlocks are available in various configurations to cater to diverse cleanroom requirements:

- Number of Doors:

- 2-door (as detailed above)

- 3-door

- 4-door

- Lock Pin Type:

- Rounded lock pins

- Rectangular lock pins

V. Applications and Advantages of Kawaoka Door Interlocks

Interlock systems play a critical role in cleanroom environments by:

- Controlling personnel entry and preventing the introduction of contaminants.

- Maintaining air pressure differentials between cleanroom zones.

Kawaoka door interlocks find application in various industries with strict contamination control requirements, including:

- Research

- Aerospace

- Bioengineering

- Pharmaceutical manufacturing

- Food processing

Conclusion:

The Kawaoka A2 cleanroom door interlock system, with its advanced features, robust construction, and diverse configurations, offers a compelling solution for maintaining a sterile and controlled environment in critical cleanroom applications.