Interlock systems help ensure safety and hygiene in factory airlocks by allowing only one door open at a time. This solution prevents cross-contamination, maintains cleanroom standards conforming to GMP, HACCP, ISO 22000, and enhances automation and safety in production.

- 1. What is an airlock interlock lock? Why is it needed in food factories?

- 2. Standards for selecting interlock locks for food factories

- 3. Benefits of using interlock locks in food factory airlocks

- 4. Reputable suppliers of interlock locks for food factories

- 5. Frequently Asked Questions about airlock interlock locks in food factories

1. What is an airlock interlock lock? Why is it needed in food factories?

Interlock system is a control system that allows only one door in an airlock zone to open at any given moment, ensuring that movement between controlled zones in a factory is done safely and hygienically. In food factories meeting GMP, HACCP, or ISO 22000 standards, interlock locks are typically installed in airlock areas - the intermediate space between two zones of different cleanliness levels (for example, from production to packaging).

Roles of interlock in food factories:

-

Prevent cross-contamination: permitting only one door to be open reduces intrusion of dust, microorganisms, or uncontrolled air from “dirty” zones into “clean” zones.

-

Control traffic flow: ensures personnel, materials, and goods move in one directional flow and reduces the risk of reverse movement causing contamination.

-

Enhance safety and automation: combined with sensors and control panels, the interlock system enables door control without manual intervention.

Example scenario – moving raw materials from dirty zone to clean zone:

Suppose a functional food factory has two zones:

- Raw material receiving (dirty zone)

- Production zone (clean zone)

Between them is an airlock chamber with two doors and an interlock lock system. When workers push a trolley with raw materials:

- The outer door (to the airlock) opens to allow materials in.

- The outer door must fully close before the inner door is allowed to open.

- After transferring materials into the clean zone, the inner door closes before the outer door can open again.

This process ensures air from the material receiving area cannot enter the production zone, while maintaining pressure differential and cleanliness.

Read more: Why is interlock a mandatory device in GMP airlock?

2. Standards for selecting interlock locks for food factories

Choosing the right type of interlock lock for airlock areas not only ensures control efficiency, but also helps the factory comply with international food safety standards such as GMP, HACCP, and ISO 22000. Below are key criteria to consider:

Hygienic, safe-to-clean materials

-

Recommended materials: stainless steel 304 or 316L - corrosion resistant and durable against cleaning agents.

-

Smooth surfaces without gaps: easier to clean and prevent accumulation of microbes or dust.

-

Able to withstand high humidity or fluctuating temperatures, common in fresh food processing or frozen-food plants.

Sequential and smart locking mechanism

-

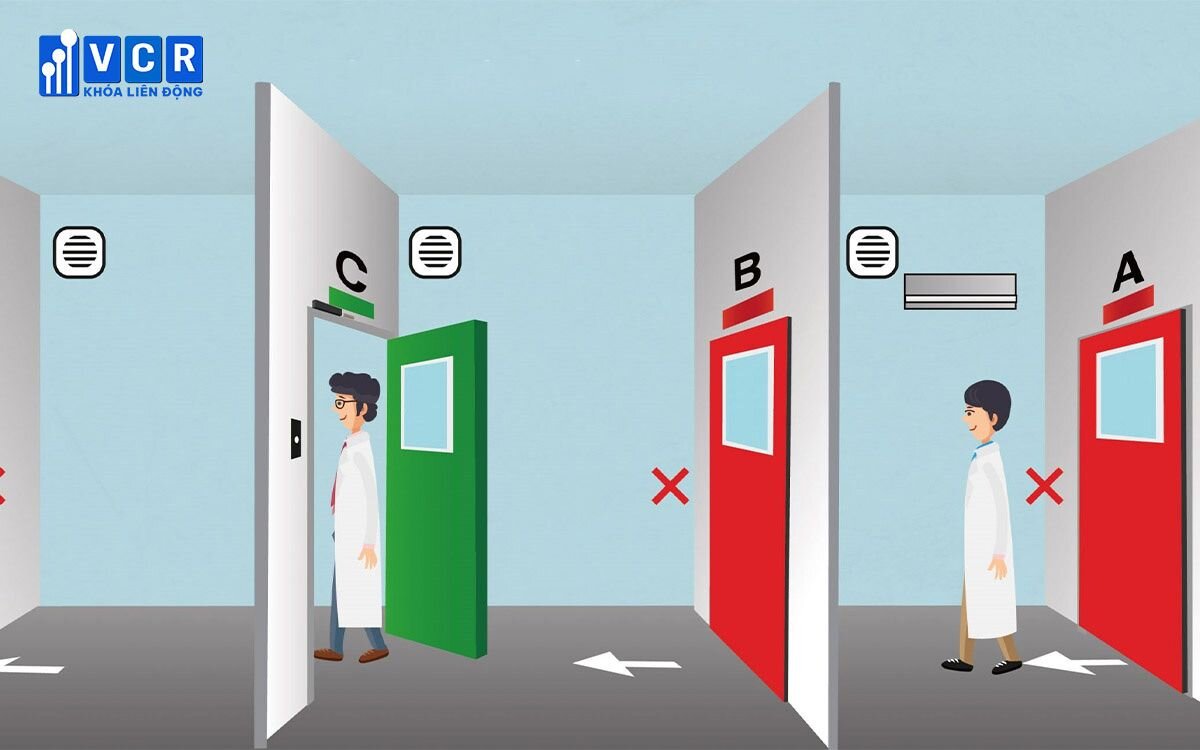

Only one door can open at a time.

-

Configurable priority modes (e.g. prioritize entrance or exit door).

-

Door status sensors, indicator lights (red/green), and alarm if operated in the wrong sequence.

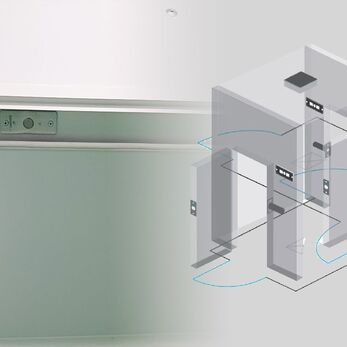

Ability to integrate with central control systems

-

Connectivity to access control systems: card, fingerprint for highly controlled areas.

-

Integration with BMS or SCADA systems: for centralized status management and remote alarms.

-

Logging of open/close events: helps trace operation history in case of incidents.

Suitability for production scale and type

-

For seafood, meat, or frozen-food factories: locks must resist high humidity and strong corrosion.

-

For confectionery, beverage factories: aesthetics and compatibility with BMS may be prioritized.

-

For functional food / GMP factories: locks integrated with traceability and access control may be required.

Conforming industry standards

-

GMP (Good Manufacturing Practice): must ensure one-way flow and reduce cross-contamination.

-

HACCP: control physical hazards in airlock operations.

-

ISO 22000: controlling physical elements (such as doors) in the food safety chain.

Read more: Why Cleanrooms Depend on Door Interlock Systems: Maintaining Airtight Integrity

3. Benefits of using interlock locks in food factory airlocks

In food production, controlling the movement of people, air, and materials between clean and non-clean zones is vital to food safety. Interlock locks are more than just door control-they bring significant advantages:

-

Prevent cross-contamination between areas

By allowing only one door to open at a time, interlock locks ensure no mixing of air between zones of different cleanliness. -

Establish unidirectional flow of people and goods

This helps avoid entering a clean zone from the dirty side, reducing contamination risks from incorrect movement. -

Enhance automation and safety

With sensors, alarms, indicator lights, and centralized control, interlock systems reduce human errors like opening the wrong door or opening multiple doors simultaneously. -

Assist in achieving international food safety certifications

They support physical control criteria in HACCP, maintain one-way flow per GMP, and are often required or recommended in ISO 22000, FSSC 22000, and BRC audits. Using interlock locks is both a technical improvement and a long-term investment in credibility and compliance.

Read more: Prepping for Success: Essential Considerations Before Cleanroom Door Interlock Installation

4. Reputable suppliers of interlock locks for food factories

Selecting the right interlock system supplier not only affects equipment quality but also the stability and standard compliance of the entire airlock system. Here are criteria to assess:

-

Experience in food factory projects

Suppliers who have completed multiple food industry deployments understand special technical requirements like cross-contamination control, pressure differentials, and hygienic material. -

Ability to advise on airlock layout and device integration

A reputable supplier should offer design support and coordinate integration with access control, HVAC, and cleanroom doors. -

Provision of certified, high-quality products

Devices should come with CO (Certificate of Origin) and CQ (Certificate of Quality). Prefer brands with clear origin from the EU, South Korea, or high-quality Vietnamese manufacturers. Some locks may include CE or RoHS certification for added trust. -

After-sales service and technical support 24/7

Since interlock systems affect continuous operations, quick technical support is essential. Prefer suppliers with in-house engineers, on-site service, and routine maintenance capabilities.

Popular interlock lock product lines today:

Depending on scale, automation, and cleanliness requirements, factories may choose among:

-

Mechanical interlock locks

Operate purely mechanically, no electricity needed, durable, low failure rate. Suitable for simple airlock areas or small factories with limited budget. -

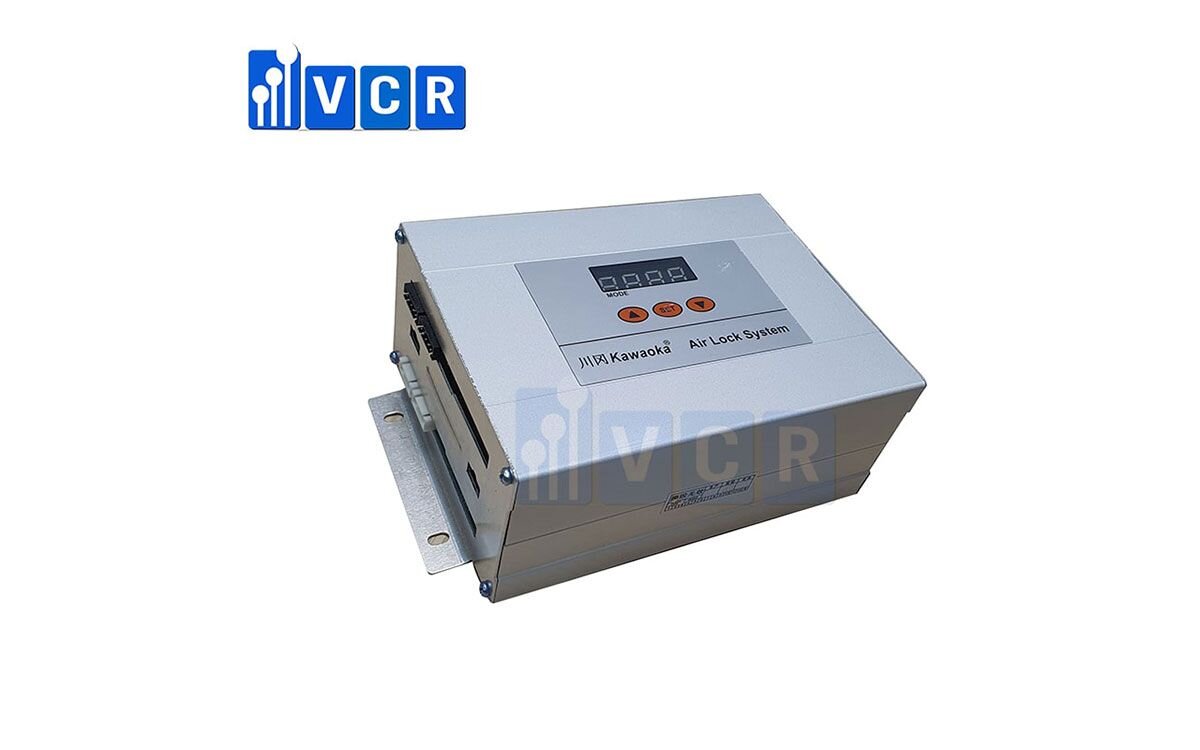

Electronic interlock locks

Powered by electricity, controlled via control panels, with status indicators and programmable sequences. More suitable for strict airlock environments, GMP or ISO standard plants. -

Interlocks integrated with access control

Combine card, fingerprint, or PIN access, logging, user access levels, and compatibility with BMS. Ideal for large factories and areas requiring restricted access (e.g. testing rooms, raw material zones).

Selection advice:

-

Small to mid-sized factories with budget constraints may use mechanical locks.

-

Factories upgrading to GMP, HACCP should consider electronic locks.

-

Large scale, tightly controlled factories may opt for locks integrated with access control systems.

Each type has its advantages; choice depends on airlock layout, budget, and cleanliness requirements.

Read more: Supplier of GMP standard clean room door interlocks

5. Frequently Asked Questions about airlock interlock locks in food factories

Q: Are interlock locks mandatory in food factories?

A: Not legally required, but strongly recommended under standards like GMP, HACCP, ISO 22000 to control cross-contamination and enforce one-way flow.

Q: Can interlock locks be retrofitted to existing doors?

A: Yes. Many suppliers offer retrofit solutions for existing doors without full replacement. However, site surveys are needed to ensure compatibility in dimensions, opening mechanism, and technical space.

Q: Will interlock locks work during a power outage?

A: Depends on the type:

-

Mechanical locks: continue functioning without electricity.

-

Electronic locks: may use a backup UPS or include a “safe mode” during power loss (e.g. both doors locked or both unlocked depending on configuration).

Q: What is the installation cost of an interlock lock?

A: Costs vary by type and number of doors:

-

Mechanical lock: 5 – 10 million VND per point

-

Electronic lock: 12 – 25 million VND per point

-

Interlock + access control: 20 – 50 million VND per point

(Costs may include control panels, wiring, accessories, installation labor)

Q: Which interlock lock brands should I choose?

A: Common and trusted brands in the food industry include:

-

BEAUFLY (Taiwan) - stable quality and good price

-

InterSafe (Korea) - good compatibility with BMS

-

VCR (Vietnam) - strong local support, layout consulting, and full warranty

If you’re looking for an optimal interlock solution to:

-

Prevent cross-contamination

-

Ensure one-way flow

-

Meet GMP, ISO 22000, FSSC standards

the VCR technical team is ready to survey, advise on layout, and propose the most suitable interlock lock solution.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Dat VCR