In the cosmetics industry, compliance with GMP – ISO 22716 standards requires strict control of movement between clean rooms to prevent cross-contamination. Interlock systems are the optimal solution, helping to maintain stable pressure, control one-way flow and meet strict validation requirements.

- 1. The Role of Interlock Systems in Cosmetic Manufacturing Facilities Complying with GMP - ISO 22716

- 2. Common Types of Interlock Systems Used in Cosmetic Manufacturing

- 3. Recommended Interlock System Selection by Area in a Cosmetic Manufacturing Facility

- 4. Interlock System Price List (Effective August 2025)

- 5. VCR’s Support Services When Purchasing Interlock Systems

- 6. FAQ - Quick Answers About Interlock Systems in Cosmetic Plants

- 7. Order Your Interlock System or Get a Free Consultation Today

1. The Role of Interlock Systems in Cosmetic Manufacturing Facilities Complying with GMP - ISO 22716

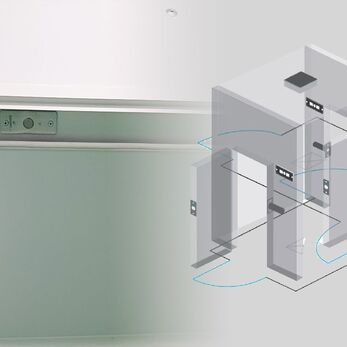

In modern cosmetic manufacturing plants—especially those operating under GMP - ISO 22716 standards—controlling movement between cleanroom areas is a critical factor to ensure product quality and prevent cross-contamination. The interlock system is a specialized device that automates this process and is typically installed at key locations such as airlocks, gowning rooms, filling rooms, and packaging areas.

Thanks to its ability to control the open/close status of multiple doors simultaneously, the interlock system plays several essential roles:

- Prevents multiple doors from opening at once - minimizing the risk of cross-contamination between rooms with different cleanliness classes.

- Maintains stable cleanroom pressure - avoiding air pressure loss and the risk of particle, dust, or microbial intrusion.

- Ensures one-way traffic flow - reducing operational errors, especially in gowning rooms or airlock transitions.

- Complies with GMP and ISO 22716 inspection requirements - making it a must-have component for contamination control protocols in the cosmetics industry.

2. Common Types of Interlock Systems Used in Cosmetic Manufacturing

In cosmetic cleanroom environments, each area such as the gowning room, filling area, or packaging zone has its own operational characteristics and contamination control requirements. Therefore, selecting the right type of interlock system for each application is not only essential for operational efficiency but also critical for compliance with GMP or ISO 22716 standards during audits.

Below is a comparison of four commonly used interlock models in cosmetic manufacturing plants:

|

Model |

Technology |

Supported Doors |

Key Features |

|

KLD-01 |

Mechanical |

2 doors |

No electricity required, easy to install and maintain |

|

KLD-02 |

Electronic relay |

2-3 doors |

Door status indicator lights, stable performance |

|

KLD-03 |

Microcontroller-based |

2-4 doors |

Audio alerts, door log tracking, ideal for critical areas |

|

KLD-Wifi |

Wireless (WiFi/RS485) |

2 doors |

Remote control, centralized monitoring, SCADA system integration |

Quick selection guide by area:

- Gowning rooms and airlocks: KLD-01 or KLD-02 - simple operation, minimal technical requirements.

- Filling or formulation rooms: KLD-03 - enables event logging and violation alerts.

- Packaging or QC areas, or rooms with SCADA: KLD-Wifi - allows centralized supervision and control.

Choosing and implementing the right interlock system for each area enhances cross-contamination control and optimizes cleanroom operations to meet international cosmetic manufacturing standards.

See more: Understanding 2-Door Interlock Systems: Maintaining Airlock Integrity in Cleanrooms

3. Recommended Interlock System Selection by Area in a Cosmetic Manufacturing Facility

Choosing the right interlock system should not be based solely on price or technology. It must be tailored to the operational characteristics and control requirements of each area within the plant. Below are specific recommendations by functional zone in a cosmetic production line:

Gowning Room - Controlling Entry into the Cleanroom

- Function: A transitional area between the external environment and the cleanroom, typically with 2 to 3 doors.

- Main Requirements:

- Control unidirectional personnel flow.

- Prevent simultaneous opening of entry and exit doors.

- Recommended Solution:

- Mechanical or electronic relay interlocks.

- Designed for 2 doors, interlocked in a cross-open configuration.

- Prioritize simple, cost-effective solutions that still ensure safe operation.

Filling & Compounding Room - High Sterility Zone

- Function: A critical zone with high contamination risk due to direct contact with raw materials and products.

- Main Requirements:

- Alert if doors are opened in the wrong sequence.

- Log door access events (for quality inspection purposes).

- Recommended Solution:

- Microcontroller-based interlocks or systems with audio/visual alarms.

- Supports 2-4 doors, with programmable logic to match plant layout.

- Ideal for facilities certified under GMP EU/ASEAN.

Packaging & Labeling Area - High Traffic & Inventory Flow

- Function: Area with constant material transfer, packaging, and outbound logistics.

- Main Requirements:

- Integration with material pass boxes and personnel air showers.

- Centralized monitoring with real-time door status visibility.

- Recommended Solution:

- SCADA-connected or WiFi-enabled interlock systems.

- Real-time monitoring and control from a centralized dashboard.

- Optimized for smart factory environments and digital transformation initiatives.

Implementing the appropriate interlock system for each functional area not only helps maintain cleanroom integrity but also facilitates ISO 22716 and GMP certification during regular audits.

See more: Buffer room and its applications in clean room

4. Interlock System Price List (Effective August 2025)

To support cosmetic manufacturers in selecting equipment that fits both technical requirements and budget, VCR has updated its interlock system price list effective from August 2025. Prices include basic technical support and installation consultation.

|

Product Name |

Retail Price (VND) |

Warranty |

Notes |

|

Mechanical Interlock |

4,800,000 |

12 months |

No power required, easy installation and maintenance |

|

Electronic Relay Interlock |

7,200,000 |

12 months |

Indicator lights, ideal for gowning rooms and airlocks |

|

Microcontroller Interlock |

9,500,000 |

12 months |

Audio alert, door access logging |

|

WiFi Interlock |

12,000,000 |

18 months |

Remote control, SCADA integration for centralized monitoring |

These prices may vary based on customization or specific project requirements. To receive a full quotation and technical layout tailored to your facility, please contact VCR directly.

5. VCR’s Support Services When Purchasing Interlock Systems

VCR not only supplies high-quality equipment but also partners with clients throughout the design, installation, and operation of interlock systems in cosmetic manufacturing plants. Every project is more than a transaction—it’s a complete solution aimed at optimizing cleanroom control processes in compliance with GMP - ISO 22716 standards.

Free Technical Consulting & Layout Design

- On-site assessment to determine the quantity and optimal placement of interlock systems.

- Customized connection diagrams for each area: gowning rooms, airlocks, pass boxes...

- Interlock selection optimized for cost-performance-compliance balance.

Customized Configuration & Programming

- Programming for sequential locking/unlocking, operation error alarms, and event logging.

- Custom functions adapted to different cosmetic production models (handmade or industrial).

- Support for integration with SCADA, HMI, or in-house BMS systems if available.

Complete Documentation & Training

- Operating manuals provided in both printed and digital PDF formats.

- Includes wiring diagrams, configuration instructions (if applicable).

- On-site training for plant technicians and QA staff.

Warranty - Maintenance - Spare Parts

- Standard warranty from 12 to 18 months, depending on the model.

- Readily available spare parts and technical support within 24 hours.

- Optional maintenance packages for plants with regular audit requirements.

With proven experience implementing interlock systems for dozens of cosmetic plants across Vietnam, VCR is committed to delivering durable, compliant, and high-performing access control solutions—helping manufacturers operate confidently and pass GMP inspections with ease.

See more: Kawaoka A2 Series - Cleanroom Interlock System

6. FAQ - Quick Answers About Interlock Systems in Cosmetic Plants

1. Is it mandatory to install interlock systems in cosmetic manufacturing plants?

Yes. According to ISO 22716 and GMP standards, transitional areas like airlocks, gowning rooms, and filling rooms must be strictly controlled to prevent cross-contamination. Interlock systems are therefore strongly recommended and often essential in GMP-compliant facilities.

2. Can electronic interlock systems be added to existing doors?

Absolutely. VCR’s interlock systems are designed for flexible integration with existing door frames. You only need to install power supply and sensors—no need to replace doors, making it a cost-effective upgrade for existing plants.

3. Do microcontroller-based interlocks log door activity history?

Yes. Several interlock models feature event logging that records door activity, useful for GMP audits and internal compliance tracking.

4. Can the interlock system be monitored or controlled remotely via central software?

Yes. The KLD-Wifi model supports WiFi or RS485 communication, easily integrating with SCADA, HMI, or BMS platforms—ideal for Industry 4.0 cosmetic manufacturing.

5. Does installing interlock systems take a long time?

Not at all. Most interlock installations require only 3-4 hours, including configuration and testing. VCR’s technical team can complete installation during downtime or scheduled maintenance windows.

For more in-depth questions about interlock systems for cosmetic manufacturing, feel free to contact the VCR technical team for direct assistance.

7. Order Your Interlock System or Get a Free Consultation Today

If you're looking for the right interlock solution for your cosmetic facility—or a detailed quotation based on your layout—VCR is here to support you from concept to installation and beyond.

What You’ll Receive When You Contact VCR:

- Detailed pricing and discount policies based on volume

- Customized layout drawings for interlock installation by area

- Consulting aligned with GMP - ISO 22716 from cleanroom experts

- Nationwide technical support with fast response times

Contact Us Now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Diep VCR