To uphold cleanliness standards, cleanrooms require an extensive array of equipment and supporting tools. One crucial component to consider when constructing a cleanroom is the buffer room. But what exactly is a buffer room and how is it utilized in clean areas?

What is a buffer room?

-

A buffer room serves as a sterile transition area situated between non-cleanroom space and cleanroom, facilitating controlled personnel entry and minimizing cross-contamination.

-

Buffer zones typically maintain a positive pressure to prevent the ingress of particle and microbial contaminants.

The ideal range for maintaining the pressure differential is between 10 to 20 pascals, with the HVAC system playing a key role in regulating both the pressure and air quality within the area.

Buffer room applications

Within the buffer room, simultaneous door openings are prohibited. Doors can only be opened when the other door is securely closed, typically enforced by an interlock system.

Standard cleanroom

-

The buffer room serves as a transitional space, aimed at blocking particles and contaminants from infiltrating the cleanroom environment.

-

Positioned between two cleanrooms, the buffer room may feature multiple doors (optional), and can be utilized jointly by two adjacent cleanrooms.

-

However, if the cleanrooms have significantly different classifications, they are not compatible for sharing a buffer room.

For instance, an ISO 8 cleanroom cannot share a buffer room with an ISO 3 cleanroom.

Negative pressure cleanroom

-

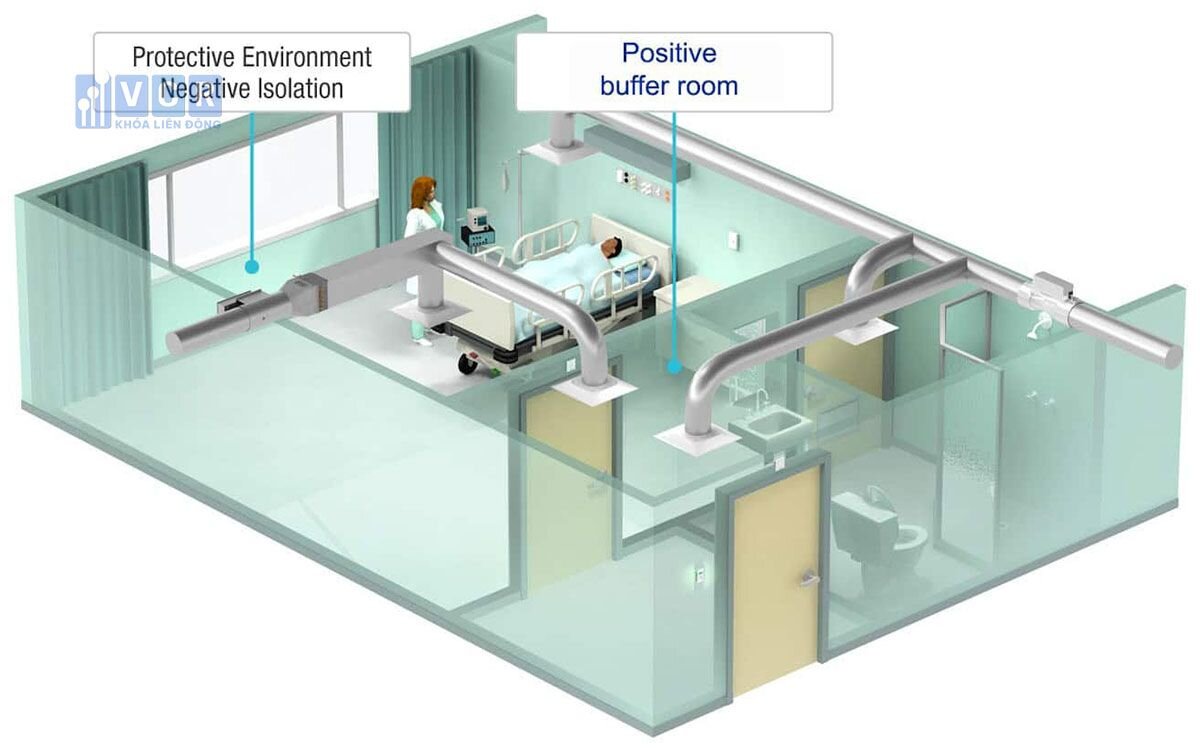

The negative pressure isolation room consists of two sections: the buffer room and the primary cleanroom.

Watch: Positive pressure room Vs. Negative pressure room

The buffer room is a small chamber situated between the hallway and the main isolation area.

Air from the external environment flows through this room, entering the negative pressure isolation space before being expelled through the air filtration system.

To learn more about the buffer room in a negative pressure room, please watch the video.

-

Individuals entering the negative pressure isolation room, such as medical personnel, are required to pass through the buffer room

Within this space, they wear protective clothing including gowns, hoods, masks, gloves, and shoe covers.

This protocol ensures that the isolation room remains uncontaminated, reducing the risk of healthy individuals coming into contact with the patient's bodily secretions such as saliva, nasal discharge, or respiratory droplets.

Subsequently, adhering to the principle of unidirectional flow, medical staff and the patient's family exit the main cleanroom through a secondary buffer room.

Here, medical equipment and protective attire are removed and disposed of in accordance with regulatory guidelines.

Buffer room design principles

-

The buffer room should have a minimum area of 3 square meters

-

The cleanliness level within the buffer room should match that of the adjoining room or area being entered, but should not exceed ISO 6 (Class 1,000)

-

It is unnecessary to incorporate a buffer room between clean rooms that are separated by a single level

Based on theoretical calculations, the introduction of pollutants upon door opening does not increase if the dust concentration in the room does not exceed 120% and the door remains open for less than 2 minutes.

-

When there is a disparity in cleanliness levels between adjacent clean rooms, the design of a buffer room should be carefully considered based on specific circumstances

Although the immediate influx of pollutants upon door opening causes a doubling of the dust concentration in the room, it typically takes about 3 minutes for the room to return to a clean state with dust concentration below 120%.

If the time required for self-cleaning is deemed acceptable or does not impact experiments or production, a buffer room may not be necessary in such cases.

-

In situations where adjacent rooms have different sources of contamination, even if they share the same cleanliness class, it is advisable to include a buffer room between them to prevent contamination

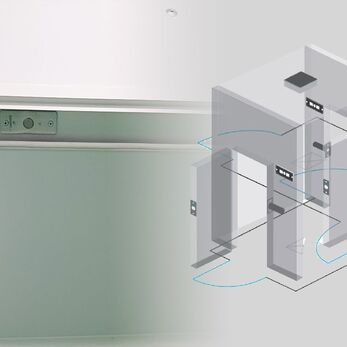

The importance of interlock in buffer room

The buffer room serves the purpose of preventing cross-contamination within the cleanroom environment. Hence, apart from maintaining clean air within this space, the buffer room must implement an interlock system.

An interlock is a specialized locking mechanism employed for controlling access to two doors simultaneously, thereby preventing cross-contamination between cleanrooms of varying cleanliness levels. When one door is opened, the interlock system automatically locks the other doors.

Read more: Different Categories Of Cleanroom Interlock

See more: Clean Room Interlock System User Manual

The difference between buffer room and airlock

In reality, there exists a significant distinction between an airlock and a buffer room.

The primary function of an airlock is to prevent the exchange of air between adjacent spaces or environments, effectively minimizing "cross-contamination". To impede the ingress of particles, the air pressure within the airlock room must be negative relative to its neighboring environment. This entails maintaining a lower air pressure in the airlock room compared to the adjacent cleanroom.

On the other hand, a buffer room is positioned between an unclean area and a clean area. The air pressure within the buffer room is higher than that of the unclean area but lower than that of the clean area. The pressure gradient from the unclean area to the buffer room to the clean area ranges from low to high. By incorporating a buffer room, the airflow from the unclean area is obstructed before it can infiltrate the clean area, thus preventing contamination.

In essence, an airlock functions as a type of buffer room. While both spaces serve similar purposes, the buffer room is equipped with a clean air system, whereas the airlock lacks this feature.

Vietnam Cleanroom Equipment (VCR) specializes in supplying cleanroom equipment to construction contractors nationwide. Our products boast high quality, competitive prices, and extensive availability. Our equipment includes:

Differential pressure gauge, FFU Fan Filter Unit, Pass box, Air filter, HEPA box, Clean booth, cleanroom steel door, Isolator cabinet, and other equipment.