Interlock System plays a vital role in ensuring controlled access and preventing cross-contamination in critical cleanroom environments.

By understanding its components and functionalities, you can contribute to maintaining a sterile and safe working space.

I. Understanding the Clean Room Interlock System

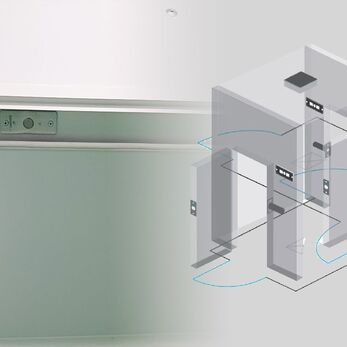

A clean room interlock system is an electronic access control device specifically designed for double-door airlock configurations. It ensures that only one door within the airlock can be opened at a time. This interlocking mechanism prevents the accidental creation of a direct path between cleanroom environments of varying cleanliness levels or between the cleanroom and non-cleanroom areas. This minimizes the risk of airborne contaminants compromising the integrity of the cleanroom.

See more: Buffer room and its applications in clean room

II. System Components

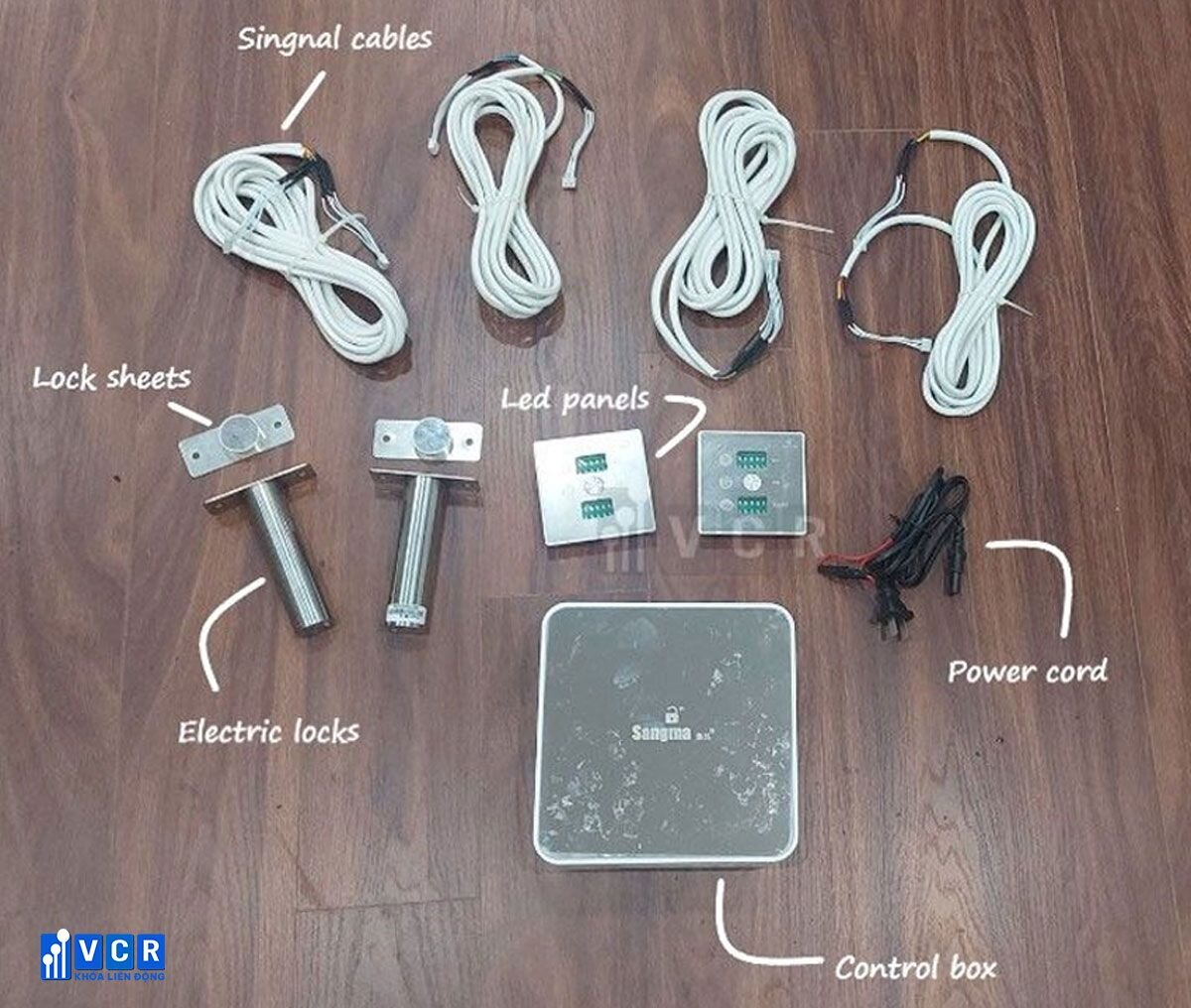

A typical clean room interlock system comprises the following key components:

1. Control Box: This central unit, typically constructed from corrosion-resistant stainless steel or plastic, houses the electronic components that govern the system's operation.

2. Electric Locks and Lock Sheets: These electromagnetic locks, fabricated from durable stainless steel, secure the airlock doors. The corresponding lock sheets are mounted on the door frames to interact with the locks.

3. LED Panels with Emergency Button: These illuminated panels provide visual status indicators. The green light signifies a ready state with permission to open a door, while the red light indicates the opposite. An emergency button is also present on the panel for manual door unlocking in case of emergencies.

4. Signal Cables and Power Cord: These cables connect the various system components and provide power to the control box.

See more: Why Cleanrooms Depend on Door Interlock Systems

III. Operating the Clean Room Interlock System

The system operates based on the following principles:

1. Interlocked Doors: Only one door within the airlock can be unlocked and opened at any given time. This ensures that a direct pathway between potentially contaminated areas is never established.

2. System Status Indicators:

- Initial Boot Beep: A single beep signifies successful system startup. Additional beeps may occur upon door opening.

- Green Light: This indicates that the system is ready and a door can be opened. However, if one door is already open, the other door will be locked and display a red light.

- Red Light: This signifies that the door cannot be opened due to the interlock mechanism or another reason (e.g., door already open).

3. Door Open Time Alarm: An audible alarm (buzzer) will sound if a door is left open for an extended period, prompting personnel to close it promptly.

4. Automatic Door Unlocking: If a door remains open for an excessive duration, the system may automatically unlock the other door to allow safe egress in case of accidental entrapment.

5. Emergency Override: In case of emergencies, pressing the dedicated button on the LED panel unlocks all doors, enabling a safe and quick exit from the airlock.

See more: Cleanroom Interlock System Installation

Additional Considerations:

- Regular Maintenance: Consult the manufacturer's recommendations for proper system maintenance, including periodic cleaning and component inspections.

- User Training: Ensure all personnel working in the cleanroom environment are adequately trained on the proper use and operation of the interlock system.

- Emergency Procedures: Familiarize yourself with the emergency procedures outlined by your facility in case of system malfunction or other unforeseen circumstances.

By following these guidelines and adhering to established protocols, you can ensure the smooth and effective operation of the clean room interlock system, thereby safeguarding the integrity of the cleanroom environment and minimizing the risk of contamination.