Interlock is a smart door control solution that allows only one door to be opened at a time to prevent pressure loss and limit dust and bacteria from entering. In food factories, this device helps ensure strict hygiene procedures, meeting GMP, HACCP and ISO 22000 standards.

1. Introduction to Interlock Systems for Food Processing Plants

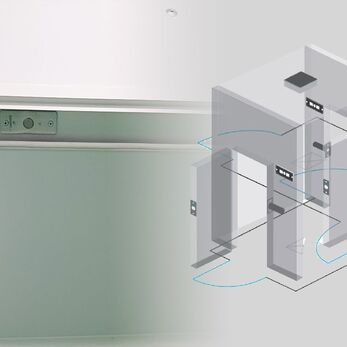

An interlock system is an intelligent door control mechanism that allows only one door to open at a time, preventing two doors from being opened simultaneously, which could cause pressure loss or allow dust and microorganisms to enter. In food processing plants, interlocks act as “gatekeepers,” ensuring that the movement of personnel and materials strictly follows hygiene protocols.

This device is essential for maintaining quality management and food safety standards such as GMP (Good Manufacturing Practice), HACCP (Hazard Analysis and Critical Control Points), and ISO 22000. By controlling access to sensitive areas like processing rooms, packaging areas, and storage rooms, interlocks help reduce cross-contamination risks, maintain required positive/negative air pressure, and protect products from contaminants.

Updating the latest interlock price list benefits businesses by optimizing investment planning, ensuring the selection of the most suitable solution for each plant’s scale, automation level, and quality control requirements. Accurate pricing information also helps the procurement team negotiate effectively and supports the technical team in selecting configurations that meet standards and ensure long service life.

2. Types of Interlock Systems

In the food industry, interlocks are designed in various forms to suit the scale and operational needs of each plant. Common types include:

2.1. Mechanical Interlocks

- Working principle: Uses mechanical latches and locks to control door opening/closing.

- Advantages: Simple, durable, does not rely on electricity, low cost.

- Disadvantages: Cannot integrate alarms or record data, limited expandability.

- Applications: Auxiliary areas or locations with minimal monitoring needs.

2.2. Electronic Interlocks

- Working principle: Uses electronic controllers, sensors, and electromagnetic locks to manage door status.

- Advantages: Programmable logic, integrates lights, alarms, and connects to monitoring systems.

- Disadvantages: Depends on electricity, higher cost than mechanical types.

- Applications: Main production areas, packaging rooms, airlocks requiring strict control.

2.3. 2-Door, 3-Door, and Multi-Door Interlock Systems

- 2-door interlock: Prevents two doors from opening simultaneously; common in single-direction changing rooms or small airlocks.

- 3-door interlock: Adds an extra control layer, often used at intersections between storage, processing, and packaging areas.

- Multi-door interlock: Large-scale systems synchronizing all access points in the production line to ensure closed-loop operation.

2.4. Interlock with Access Control – HVAC Integration

- Access control integration: Manages entry via card, PIN, or biometric authentication.

- HVAC integration: Links with air conditioning and filtration systems to maintain pressure, temperature, and humidity standards.

- Advantages: Enhances automation, ensures both security and environmental quality.

- Applications: Large-scale food factories with stringent environmental control requirements.

3. Comparison Table of Interlock Types

|

Interlock Type |

Operating Principle |

Advantages |

Disadvantages |

|

Mechanical |

Mechanical latch & lock |

Durable, no electricity needed, low cost |

No alarms, no data logging |

|

Electronic |

Controller & electromagnetic lock |

Integrated lights/alarms, flexible programming |

Electricity-dependent, higher cost |

|

2-door |

Links 2 doors, only one can open at a time |

Easy installation, effective control |

Not suitable for complex layouts |

|

3-door |

Sequentially linked 3-door system |

Higher security, GMP compliance |

Complex setup, higher cost |

|

Access Control + HVAC |

Interlock + card/PIN + HVAC |

Access management, maintains environment |

High investment, technical requirements |

This comparison helps managers and procurement teams evaluate the pros and cons of each interlock type to choose the optimal solution for performance and cost.

4. Latest Interlock Price List (Update 2025)

|

Interlock Type |

Price Range (VND/set) |

Included Components |

Common Applications |

|

Mechanical |

6,500,000 – 8,500,000 |

Mechanical latch, lock, door mounting accessories |

Auxiliary rooms, storage, low-monitoring areas |

|

Electronic 2-door |

12,000,000 – 15,000,000 |

Central controller, electromagnetic lock, alarm lights/sound, door sensors |

Airlocks, changing rooms, small packaging rooms |

|

Electronic 3-door |

18,000,000 – 25,000,000 |

Multi-door controller, electromagnetic lock, signaling system, programmable logic |

Processing – packaging – storage zones |

|

Advanced Integrated |

From 30,000,000 |

Electronic interlock + access control (card, PIN, biometrics) + HVAC integration |

Large-scale plants with strict environmental control |

Note: Prices may vary depending on configuration, number of doors, additional features, and supplier. Businesses should request a detailed quote with technical drawings to ensure compliance with GMP, HACCP, ISO 22000.

See more: VCR interlock lines are popular with customers

5. Factors Affecting Price

- The more doors that need to be interlocked, the higher the cost of equipment and installation.

- 2-door systems are usually simpler and cheaper than 3-door or multiple-door interconnections.

- Complex configurations require multi-channel controllers and in-depth logic programming, which increases the cost.

- Door sensors: Ensure the system recognizes the correct open/close status.

- Alarms & signal lights: Warn when the door is opened incorrectly, increasing safety.

- HVAC connection: Link to the air conditioning and air filtration system to maintain standard pressure, temperature and humidity.

- Each additional feature increases the cost of equipment and programming.

- Wet, low temperature or chemical environments require corrosion-resistant materials such as 304/316 stainless steel.

- Heavy or large doors require higher-load electromagnetic locks and hinges, resulting in higher prices.

- Frozen food or seafood processing plants often require anti-frost solutions for interlock systems.

- These standards strictly regulate traffic flow, cross-contamination control and hygiene safety.

- A qualified interlock system often requires additional monitoring features, storing door opening data and connecting to a quality management system.

- Meeting high standards means that equipment and construction costs also increase accordingly.

6. Recommendations for Choosing Interlocks

- Practical experience: Prioritize units that have implemented interlocks for food factories that meet GMP, HACCP, ISO 22000 standards.

- Technical consulting ability: Can provide optimal solutions based on flow diagrams and control requirements.

- Product quality: Use durable components that meet electrical safety and anti-corrosion standards.

- After-sales service: Support warranty, maintenance and provide spare parts quickly.

- Changing room, small airlock: Only need basic 2-door mechanical or electronic interlock.

- Processing and packaging areas: Should use electronic interlocks with alarms and indicator lights to ensure strict compliance with procedures.

- Warehouses or special areas: Can use interlocks with integrated access control to limit unauthorized personnel.

- Large-scale factories: Should integrate interlocks with HVAC systems to maintain pressure and production environment.

- Warranty: Choose products with a minimum warranty period of 12–24 months.

- Periodic maintenance: Check the operation of locks, sensors, lights/buzzers and controllers to ensure stability.

- Replacement parts: Should choose popular types with easy-to-find accessories to reduce production downtime when repairs are needed.

See more: Airlocks and Access control

7. FAQ

8. Contact for Pricing & Solutions

VCR Commitments:

- International-standard products (GMP, HACCP, ISO 22000).

- Cost-optimized solutions tailored to each business.

- End-to-end services from survey to maintenance.

- Fast technical support within 24 hours.

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com

Diep VCR