Electronic cleanroom interlock locks are an automatic door-control solution designed to maintain differential pressure and prevent cross-contamination between cleanroom zones. With flexible customization, high stability, and easy GMP system integration, this device is an optimal choice for modern factories.

- What Is an Electronic Cleanroom Interlock Lock?

- Why Businesses Should Choose High-Quality Electronic Interlock Locks

- Criteria for Choosing a Reputable Electronic Interlock Lock Supplier

- Introducing VCR - A Leading Supplier of Cleanroom Interlock Locks

- Ordering & Deployment Process at VCR

- Electronic vs Mechanical Interlock Locks: Which Is Better for Cleanrooms?

- Frequently Asked Questions (FAQ)

What Is an Electronic Cleanroom Interlock Lock?

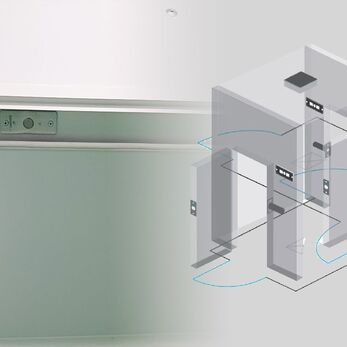

An cleanroom interlock lock is a control device that automates door open/close functions to ensure that at any given moment, only one door in the same cleanroom area can be open. This solution strictly controls flow of movement and room pressure, preventing cross-contamination between different cleanliness zones.

Basic Structure & Operating Principle

Comparison with Mechanical Interlock Locks

| Criterion | Mechanical Lock | Electronic Lock |

|---|---|---|

| Operating mechanism | Mechanical | Electronic / microcontroller |

| Configuration flexibility | Limited | High |

| System integration | No | Yes (can integrate with other systems) |

| Durability & stability | Medium | High |

| Suitability for GMP cleanrooms | Limited | Well suited |

Mechanical interlock locks cost less but lack flexibility and are difficult to integrate into centralized management systems. In contrast, electronic interlock locks allow flexible configuration across multiple doors and provide better operational safety.

Read more: Latest price list of Interlock used in electronics factory

Why Businesses Should Choose High-Quality Electronic Interlock Locks

In a modern cleanroom setup, selecting compliant devices affects both operational efficiency and environmental control. High-quality electronic interlock locks are a vital component that demand careful attention.

Prevent simultaneous door opening - the key function is to prevent two or more doors from opening at once in a zone. If simultaneous opening occurs:

- Clean airflow is lost and room pressure drops

- Cross-contamination may happen

- Material and personnel flow controls fail

Using a reliable interlock lock ensures trustworthy operation and prevents disruptions in the production line.

Stable long-term operation

Electronic lock systems operate continuously, especially in high-use areas like airlocks and changing rooms. Poor quality devices may suffer from:

- Signal lag or imprecise open/close

- Sensor or controller failure over time

- Disruption to overall cleanroom control processes

Choosing a trustworthy supplier reduces maintenance costs, extends device life, and minimizes operational downtime.

Easy integration with control systems

Modern electronic interlock locks can synchronously connect with:

- HVAC systems: maintain room pressure per preset values

- Access control: fingerprint, card, PIN

- Central alarms: alerts when protocols are breached

Strong compatibility makes it easier for companies to expand or upgrade their systems later.

Compliance with GMP and ISO cleanroom standards

Industries such as pharmaceuticals, medical devices, electronics, and cosmetics strictly require GMP and ISO 14644 compliance. Opting for high-quality electronic interlock locks helps meet these standards and demonstrates professional production management.

Read more: Cleanroom Interlock System Installation: A Step-by-Step Guide

Criteria for Choosing a Reputable Electronic Interlock Lock Supplier

In stringent cleanroom operations, selecting the wrong supplier could jeopardize the entire system. To ensure investment effectiveness and operational safety, companies should prioritize suppliers meeting these criteria:

Deep cleanroom industry experience

Suppliers with experience in real-world cleanroom projects better understand technical demands, regulations, and potential risks. They not only deliver hardware but also advise on solutions tailored to different production models (ISO 5-ISO 8 cleanrooms, airlocks, material/personnel flows, humidity/temperature control, etc.).

Comprehensive solution capability

Electronic interlock locks work in a system context. A reputable provider should offer integration with:

- Cleanroom doors (panel, stainless steel, powder-coated steel)

- Access control systems

- Alarm systems

- HVAC, pressure control systems

Choosing an end-to-end provider helps avoid technical conflicts and simplifies maintenance.

Clear warranty & 24/7 support

Because interlock locks are sensitive devices, it’s important to opt for suppliers that provide:

- Minimum 12-month official warranty

- Nationwide on-site technical support

- Spare parts inventory

- 24/7 hotline support

Strong after-sales service underpins long-term reliability.

Track record across industries

Companies who have implemented interlock systems in pharmaceutical, food, electronics, cosmetics fields demonstrate versatility in handling diverse technical requirements. Real-world deployments are the clearest measure of supplier capability.

Read more: What is Interlock Doors? Understanding Cleanroom Interlocks

Introducing VCR - A Leading Supplier of Cleanroom Interlock Locks

With over 10 years of specialized experience in cleanroom equipment, VCR is a trusted partner for hundreds of enterprises in the pharmaceutical, food, electronics, and cosmetics sectors in Vietnam. VCR delivers not just devices but full solutions, helping clients operate stably and comply with international standards (GMP, ISO 14644).

Modern, optimal interlock solutions for cleanrooms

-

Employ microcontroller technology with electromagnetic interference (EMC) protection, ensuring accurate operation in environments with many electrical devices

-

Easy integration with existing cleanroom systems (access control, HVAC, alarm, central monitoring software)

-

Rapid installation and simple operation: VCR’s engineering team surveys, installs, and hands over with minimal disruption

-

Compatibility with many door types: powder-coated steel, panel doors, cleanroom aluminum-glass doors, stainless steel

-

Genuine device assurance, tested quality standards, warranty of 12-24 months, on-call technical support nationwide

VCR accompanies clients from survey, procurement, installation, to operation and system extension.

Read more: Why Cleanrooms Depend on Door Interlock Systems: Maintaining Airtight Integrity

Ordering & Deployment Process at VCR

VCR implements a clear, professional deployment process to help businesses integrate an electronic interlock system into real-world operations. Each step is managed by experienced technicians to ensure precision and high effectiveness.

Receive customer request

Companies contact VCR via phone, email, or online form to:

- Request consultation or quote

- Provide basic info: number of doors, usage objectives, cleanroom grades

- Schedule a survey

On-site survey

VCR engineers visit the site to:

- Assess door and physical conditions

- Check installation space, power supplies, wall structures

- Note special integration requirements (access control, alarm, BMS…)

Propose solution

Based on the survey:

- Recommend suitable interlock electronic lock systems

- Provide wiring diagrams and connection schematics

- Offer detailed quotation and deployment timeline

Installation and testing

- Installation by specialized technicians

- Ensure safety, minimal interference with ongoing cleanroom operations

- Perform trial runs and check system stability per programmed sequence

User training and handover

After setup, VCR:

- Hands over devices and operation manuals

- Trains on-site operators or technicians

- Provides wiring diagrams, control logic, and signal encoding

Periodic maintenance & after-sales support

- Schedule regular system checks

- Maintain components and check control signals

- Provide 24/7 support for any operational issues

Read more: Clean Room Interlock System User Manual: Maintaining a Sterile Environment

Electronic vs Mechanical Interlock Locks: Which Is Better for Cleanrooms?

Companies often choose between mechanical and electronic interlock locks for cleanroom doors. These two types differ significantly in operation, safety, and integration potential. The comparison below aids in evaluating the right choice:

Mechanical interlock:

- Simpler mechanism

- Moderate safety

- No system integration

- Limited configuration flexibility

- Suitable for basic cleanrooms with minimal requirements and lower cost

Electronic interlock:

- Controlled by microcontroller

- Higher safety and precision

- Compatible integration with HVAC, access, alarm systems

- Highly configurable for multiple doors and control flows

- Well-suited for modern cleanrooms under stringent standards like GMP, ISO

Conclusion: Mechanical locks may work for simple cleanrooms, but electronic locks are the ideal choice in modern facilities demanding smart control and high safety levels.

Read more: Supplier of GMP standard clean room door interlocks

Frequently Asked Questions (FAQ)

What happens if there is a power outage?

The electronic interlock system can be configured for safe behavior during power loss. Depending on business needs, VCR offers options like:

-

Back-up battery (UPS) to maintain operation for a set period

-

Emergency door-open mode: default to open to avoid blocking emergency exits

Can the interlock lock connect to an access control system?

Yes. VCR’s electronic interlock models support integration with technologies such as:

-

Card access

-

PIN code

-

Fingerprint

-

Facial recognition (optional)

This setup synchronizes personnel flow control with overall security management.

How long does installation take?

It depends on:

-

Number of interlocked doors

-

Existing infrastructure (power, space, setup)

Typically, installation takes 1-2 working days. For complex projects, VCR plans rollout to avoid disrupting production.

Is it compatible with panel doors?

Yes. VCR provides electronic lock types compatible with many cleanroom door materials, including:

-

EPS or PU panel doors

-

Cleanroom aluminum-glass doors

-

Powder-coated steel doors

-

Stainless steel doors

Depending on the door, VCR recommends the suitable lock model and accessories to ensure tight sealing and secure operation.

If your business is seeking a secure, stable, and easily integratable electronic cleanroom interlock solution, let VCR assist you from site survey through to installation and operation.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Dat VCR