In modern electronics manufacturing environments, especially SMT lines, cleanroom flow control and differential pressure are vital to protect micro-components from dust and static electricity. Cleanroom interlocks are an important “gatekeeper” solution, helping to maintain stable differential pressure and prevent cross-contamination.

- 1. Interlock System - The "Gatekeeper" of Electronic Cleanrooms

- 2. Key Factors Affecting Cleanroom Interlock System Pricing

- 3. Cleanroom Interlock System Price List (Updated for 2025)

- 4. Recommendations for Choosing Interlock Systems by Area in Electronics Factories

- 5. VCR Pricing & Technical Support Policy

- 6. FAQ - Quick Answers About Cleanroom Interlock Systems

- 7. Contact Us Now for a Free Consultation & Detailed Quote

1. Interlock System - The "Gatekeeper" of Electronic Cleanrooms

In electronic manufacturing environments, especially SMT (Surface Mount Technology) lines, cleanrooms are not only mandatory to protect sensitive components from dust and static electricity, but also essential for controlling airflow and pressure between zones.

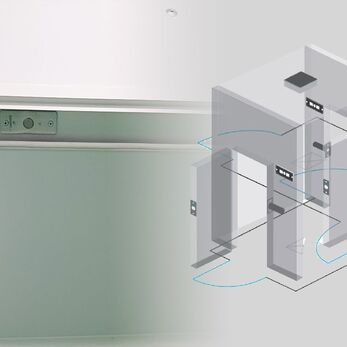

Cleanroom interlock systems serve as critical “gatekeepers” that help ensure:

- Only one door opens at a time, preventing cross-contamination between zones with different cleanliness levels.

- Pressure differentials are maintained to direct clean airflow properly.

- Cross-contamination from personnel, materials, or equipment is minimized when passing through airlocks or sensitive areas.

In practice, many incidents involving dust particle contamination, ESD damage, or component failure stem from seemingly minor door control issues - problems that a well-designed electronic interlock system can completely prevent.

Why are electronics factories racing to install interlock systems?

Vietnam’s electronics sector is rapidly expanding, with new factories producing chips, PCBs, and advanced technology devices. This growth drives the need to upgrade cleanroom infrastructure, particularly:

- Adding airlocks, gowning rooms, and ESD weighing rooms

- Upgrading from mechanical doors to smart interlock systems

- Integrating pressure monitoring, door status indicators, and central control units

As a result, understanding and updating interlock pricing has become a practical necessity for maintenance managers, cleanroom engineers, and HVAC/cleanroom system consultants.

2. Key Factors Affecting Cleanroom Interlock System Pricing

On today’s market, the price of cleanroom interlock systems can range from a few million to tens of millions of VND, depending on configuration and technical requirements. To select the right system for your budget and operational needs, it’s essential to understand the main factors influencing the cost:

1. Type of Interlock System: Mechanical - Electronic - Smart Sensor-Based

- Mechanical interlock: Operates with a basic mechanical latch, typically used for basic 2-door systems. It is cost-effective but lacks expandability or logic control.

- Electronic interlock: Uses electrical signals to control door locking/unlocking. These can be integrated into centralized systems and are well-suited for modern cleanrooms.

- Sensor-based smart interlock: Allows for flexible scenario programming (e.g., only opens when pressure differential is correct). Commonly used in SMT lines requiring high precision.

2. Number of Interlocked Doors: 2 - 3 - Multi-door Systems

- 2-door systems: The most common setup for basic airlocks.

- 3-door systems: Ideal for gowning rooms or areas with multiple material/personnel flows.

- Multi-door systems (4-6 doors or more): Require a central control unit and logic management software. These setups are more complex and therefore more expensive.

3. Additional Features

- Audible alarms & door status indicators: Help users easily identify whether a door is open or locked.

- Touchscreen control panels: Allow for intuitive programming and real-time display of door status.

- Pressure differential monitoring & fault alerts: Enhance safety in sensitive production zones.

4. Component Origin & Compliance with Technical Standards

- Imported components from Germany, Japan, or South Korea offer higher durability and precision, but at a higher cost than domestic options.

- Compliance with cleanroom standards such as ISO 14644-1, ESD, or GMP also affects pricing due to certification and specialized design requirements.

Conclusion:

When comparing interlock system quotes, don’t just look at the final price - evaluate the full picture: intended use, integration level, and scalability. Choosing the right configuration from the start will save you considerable upgrade costs in the long run.

See more: Buffer room and its applications in clean room

3. Cleanroom Interlock System Price List (Updated for 2025)

To help electronics factories plan their budgets and choose suitable equipment, here is a reference price list for popular cleanroom interlock models provided by VCR. Prices may vary depending on configuration, order quantity, and on-site installation requirements.

|

Model |

Number of Doors |

Key Features |

Estimated Price (VND) |

Notes |

|

VCR‑X2S |

2 doors |

Standard model with basic electrical signal integration |

2,500,000 - 3,500,000 |

Ideal for small airlock areas |

|

VCR‑X2M |

2 doors |

Supports advanced logic programming |

3,200,000 - 4,800,000 |

Connects to central control systems |

|

SM2‑861S / SM2T |

2 doors |

Equipped with status sensors and door alarm |

3,000,000 - 5,000,000 |

Easy integration with HVAC systems |

|

VCR‑X3S / SM3C |

3 doors |

Independent door control with anti-simultaneous open |

4,800,000 - 6,500,000 |

Suitable for 3-stage gowning rooms |

|

Central Control Unit |

4-6 doors |

Manages multiple interlock points, includes touchscreen |

7,000,000 - 12,000,000 |

Logic customization available |

Notes:

- Prices exclude VAT and installation fees.

- VCR offers custom design services based on your cleanroom layout.

- Attractive discounts are available for bulk orders or full-package projects.

Customer Tip:

If you're planning a multi-door interlock system (3 or more doors), or need pressure differential monitoring or alarm integration, contact the VCR technical team for a tailored design and pricing proposal.

4. Recommendations for Choosing Interlock Systems by Area in Electronics Factories

Selecting the right type of interlock system not only ensures optimal environmental control but also helps manage investment costs effectively across different zones of an electronics facility. Below are practical recommendations for key functional areas:

SMT Area - Surface Mount Technology Lines

- Environmental Impact: Requires strict control of dust, static electricity, and pressure differentials.

- Recommended Lock: 2-door electronic interlock system with sensors and precise logic control.

- Why: Prevents simultaneous door openings, protecting sensitive components from particle exposure or static discharge.

- Recommended Models: VCR‑X2M, SM2‑861S.

Gowning Room - Transition Area to Cleanroom

- Environmental Impact: Serves as a buffer between external environments and cleanroom zones; high risk of cross-contamination.

- Recommended Lock: 3-door interlock system with status indicators and alarm notifications.

- Why: Ensures one-way flow and compliance with gowning, handwashing, and sanitization protocols.

- Recommended Models: VCR‑X3S, SM3C.

ESD-Sensitive Weighing Room (ICs, PCBs, Chips)

- Environmental Impact: Components are highly sensitive to ESD; require complete isolation and controlled access.

- Recommended Lock: Electronic interlock system with ESD access control (grounding verification).

- Why: Restricts access to only ESD-compliant personnel, integrates with ESD testers or touchscreens.

- Recommended Models: SM2T, customized systems with ESD control.

Tip for Selecting the Right System: Always base your decision on your cleanroom layout and actual operating procedures. VCR offers free consultations and layout-based interlock design support tailored to each production line.

See more: Different Categories Of Cleanroom Interlock

5. VCR Pricing & Technical Support Policy

As a pioneer in cleanroom-specific interlock systems, VCR does more than just supply products—we provide end-to-end support for factories, from technical consulting to installation and maintenance. Here are our key support policies for electronics industry clients:

Project-Based Quotation & Bulk Order Discounts

Every facility has unique configurations and layouts, so VCR does not apply fixed pricing. Instead, we offer flexible quotes based on:

- Type of lock & number of doors to interlock

- Additional features: alarms, ESD modules, touchscreens

- On-site installation requirements

Volume discounts from 5-20% apply to large orders or bundled cleanroom solutions (e.g., Pass Box, Air Shower, FFU).

Free Interlock Layout Consultation

VCR’s engineering team provides free interlock system layout consultation for:

- One-way / two-way / three-way gowning rooms

- Weighing rooms and material transfer zones

- Interlock systems integrated with HVAC and pressure control

Wiring diagrams and logic control drawings are also provided to facilitate quick implementation by your technical team.

Nationwide Installation & Maintenance Support

VCR has a technical service network covering major industrial zones like Bac Ninh, Hai Phong, Ho Chi Minh City, Binh Duong, and Da Nang.

Our services include:

- On-site installation & operational guidance

- Periodic maintenance under contract

- Genuine spare parts supplied within 24-48 hours

VCR Commitments:

- Consultations tailored to industry, layout, and ISO/ESD standards.

- Quotation responses within 24 hours.

- Fast delivery and 12-24 month warranty depending on the model.

See more: Why Cleanrooms Depend on Door Interlock Systems: Maintaining Airtight Integrity

6. FAQ - Quick Answers About Cleanroom Interlock Systems

1. Do electronic interlock systems require regular maintenance?

Yes. To ensure stable operation and synchronization between doors, maintenance should be performed at least every 6 months. This includes checking the power supply, control signals, magnetic locks, and any built-in alarm or indicator functions.

2. Can a mechanical interlock system be upgraded to an electronic one?

Absolutely. However, it requires an assessment of your current setup, including:

- Distance between doors

- Concealed or surface-mounted wiring system

- Available power supply

VCR can assist in redesigning the interlock layout and provide the right conversion kit without replacing the entire system.

3. How long is the delivery time after placing an order?

Standard delivery time is 3-5 working days. Popular models like VCR-X2S or SM2T are often available in stock in Hanoi and Ho Chi Minh City, so they may ship sooner for domestic orders. Custom or multi-door systems may take 7-10 days to deliver.

7. Contact Us Now for a Free Consultation & Detailed Quote

Are you planning to upgrade your cleanroom system? Need a quick quote for interlock devices based on your facility layout?

Call VCR’s technical team today to receive:

- Free interlock layout consultation based on your actual cleanroom design

- Quotation within 24 hours

- On-site technical support at your industrial zone

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Diep VCR