In the realm of cleanrooms, where meticulous control over airborne particles, temperature, pressure, and humidity is paramount, strict access control plays a crucial role in maintaining sterility.

This is where cleanroom door interlock systems emerge as indispensable safeguards.

I. Understanding Door Interlock Systems

1. Definition:

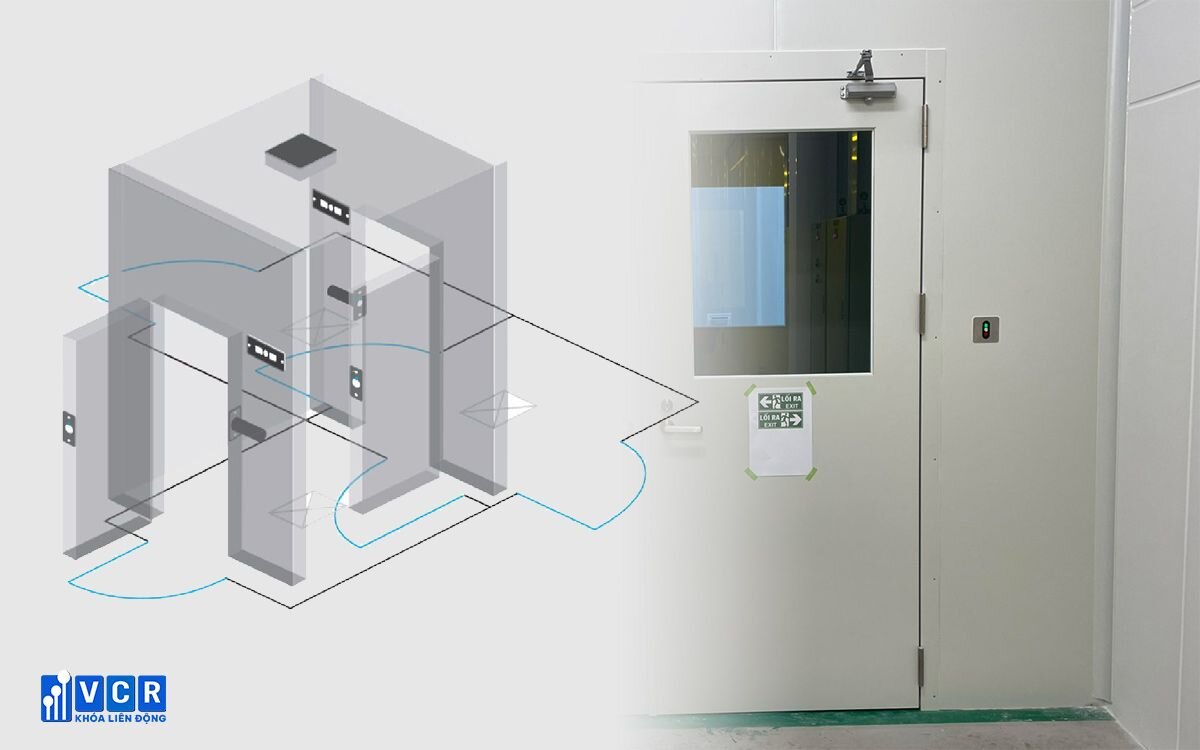

A door interlock system is an electronic device that synchronizes the opening and closing of two or more doors, typically within an airlock. This system ensures that only one door can be opened at a time, effectively preventing the simultaneous opening of both doors.

2. Functionality:

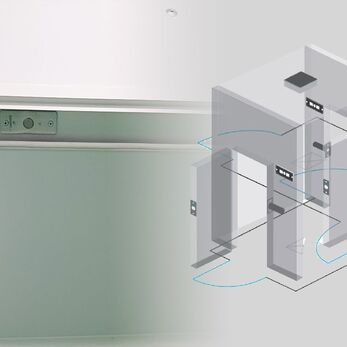

The door interlock system achieves this synchronization through a series of interconnected components, including:

- Control Box: This central unit houses the system's intelligence, processing signals and controlling door operations.

- Electric Locks: These electromagnetic locks, typically constructed from durable stainless steel, secure the doors when shut.

- LED Indicators: Located near each door, these visual indicators display the current door status (open/closed) and may also provide additional alerts.

- Wiring and Cables: These connect the various components and provide power to the system.

See more: Kawaoka A2 Interlock System

II. The Necessity of Door Interlock Systems in Cleanrooms

1. Preserving Airtightness and Preventing Contamination:

Cleanrooms are designed to maintain a controlled environment with minimal airborne contaminants. Their airtightness is crucial to prevent the influx of particulate matter and microorganisms from adjacent areas. However, frequent opening and closing of doors can compromise this airtightness, potentially leading to contamination.

See more: 2-Door Interlock Systems

2. Addressing Human Error and Ensuring Compliance:

Door interlock systems effectively mitigate the risk of human error by preventing both doors from being opened simultaneously. This safeguard addresses situations where personnel might unintentionally leave a door open or attempt to open both doors at once, which could significantly compromise air quality within the cleanroom.

3. Adhering to Regulatory Requirements:

Regulatory bodies, such as the EU GMP Annex 1, mandate the use of interlocking systems in airlocks leading to Grade A and B cleanrooms to prevent simultaneous opening of both doors. This regulation underscores the critical role of interlock systems in maintaining a compliant and controlled cleanroom environment.

III. Other Applications of Cleanroom Door Interlock Systems

Beyond airlocks, door interlock systems find application in various cleanroom elements, including:

- Pass boxes (transfer hatches): These boxes, used for transferring materials between areas, often utilize interlocks to ensure only one door opens at a time, minimizing the risk of contamination during material transfer.

- Air Shower: Interlocks are also used in airshowers to ensure there is no cross-contamination during the air blowing process, because this device is often placed between two environments with a difference in cleanliness.

See more: Cleanroom Interlock System Installation

Conclusion:

Cleanroom door interlock systems serve as invaluable guardians of airtightness, contamination control, and regulatory compliance within cleanrooms. By synchronizing door operation and preventing human error, they contribute significantly to maintaining the sterile and controlled environment that is essential for various applications in research, pharmaceuticals, and other sensitive industries.