Within the realm of cleanrooms, interlock doors play a critical role in safeguarding the controlled environment.

These specialized doors, equipped with an interlock system, are designed to synchronize the opening and closing of multiple doors, effectively preventing cross-contamination.

I. Unveiling the Interlock Door

1. What is Interlock

Interlock stands as a specialized locking mechanism employed for regulating access to two or more doors simultaneously. It operates by ensuring that the status of one door differs from others, thereby preventing cross-contamination between cleanrooms and non-clean areas.

See more: Buffer room and its applications in clean room

2. Advantages of Interlocks

Interlocks serve as guardians of cleanroom integrity by synchronizing the opening and closing of doors. For instance, when door 1 (connecting the airlock to the non-clean area) opens, door 2 (linking the airlock to the clean area) automatically closes. As long as door 1 remains open, door 2 remains locked, and vice versa. This mechanism ensures that only one door can be open at a time, preventing uncontrolled airflow from compromising the cleanliness of the sterile environment.

See more: What is Cleanroom Airlock

3. Applications

Interlock doors find extensive application in various settings demanding stringent contamination control, including:

- Cleanrooms

- Sterile rooms in laboratories

- Pharmaceutical cleanrooms

- Isolation rooms

II. The Necessity of Interlocks in Cleanrooms

Cleanrooms are meticulously engineered environments tailored to stringent requirements concerning air quality, temperature, and humidity. For instance, operating theaters demand sterility, while facilities involved in pharmaceutical manufacturing, electronics assembly, and food processing necessitate controlled cleanliness levels.

Maintaining cleanliness entails strict adherence to particle concentration standards, often dictated by regulations like ISO/TC209 14644-1. For instance, in ISO Class 1 cleanrooms, particle concentration above 0.2 μm must not exceed 12 particles per cubic meter of air.

See more: Clean Room Interlock System User Manual

Moreover, not all cleanrooms within a facility possess identical environmental parameters. Vaccine production areas, for instance, have distinct cleanliness requirements compared to spaces manufacturing ointments or powders. Additionally, airlocks are strategically placed to demarcate clean zones from regular areas.

Given that air typically flows from high-pressure to low-pressure zones, it's critical to prevent unwanted airflow between clean and non-clean areas. Failure to do so risks contaminating the pristine environment with unfiltered air containing pathogens and particulate matter.

III. The Interlock System: An In-Depth Look

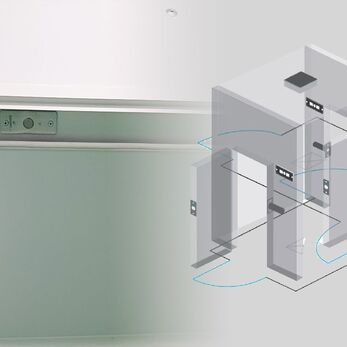

The interlock system constitutes the heart of an interlock door. It comprises several key components:

- Control Box: Often constructed from durable aluminum for optimal corrosion resistance, the control box houses the electronic components that orchestrate the system's operation.

- LED Light Indicators: These visual indicators, typically located adjacent to each door, display the current door status (open/closed) and may also provide additional alerts.

- Electric Locks and Lock Sheets: Fabricated from stainless steel for strength and reliability, these electromagnetic locks secure the doors when shut. The corresponding lock sheets are mounted on the door frames to interact with the locks.

- Wiring and Cables: These connect the various components and provide power to the system.

See more: Why Cleanrooms Depend on Door Interlock Systems

IV. Common Interlock Door Configurations

Interlock Cleanroom doors are available in various configurations to cater to diverse cleanroom requirements:

- 2-Door Interlock: This is the most common configuration, ideal for basic airlock applications.

- 3-Door Interlock: This configuration offers increased control in situations requiring passage through multiple cleanroom zones.

- 4-Door Interlock: This configuration caters to more complex cleanroom layouts and high-traffic areas.

See more: Cleanroom Interlock System Installation

Conclusion:

Interlock doors, with their integrated cleanroom interlock systems, serve as essential safeguards in cleanroom environments. By ensuring proper access control and preventing cross-contamination, they contribute significantly to maintaining the sterility and integrity of these critical controlled spaces.