Two-door interlock systems play a crucial role in ensuring a controlled and protected environment within cleanrooms.

This article delves into the functionalities, components, and applications of these systems, empowering cleanroom professionals to make informed decisions.

I. The Function of 2-Door Interlock Systems

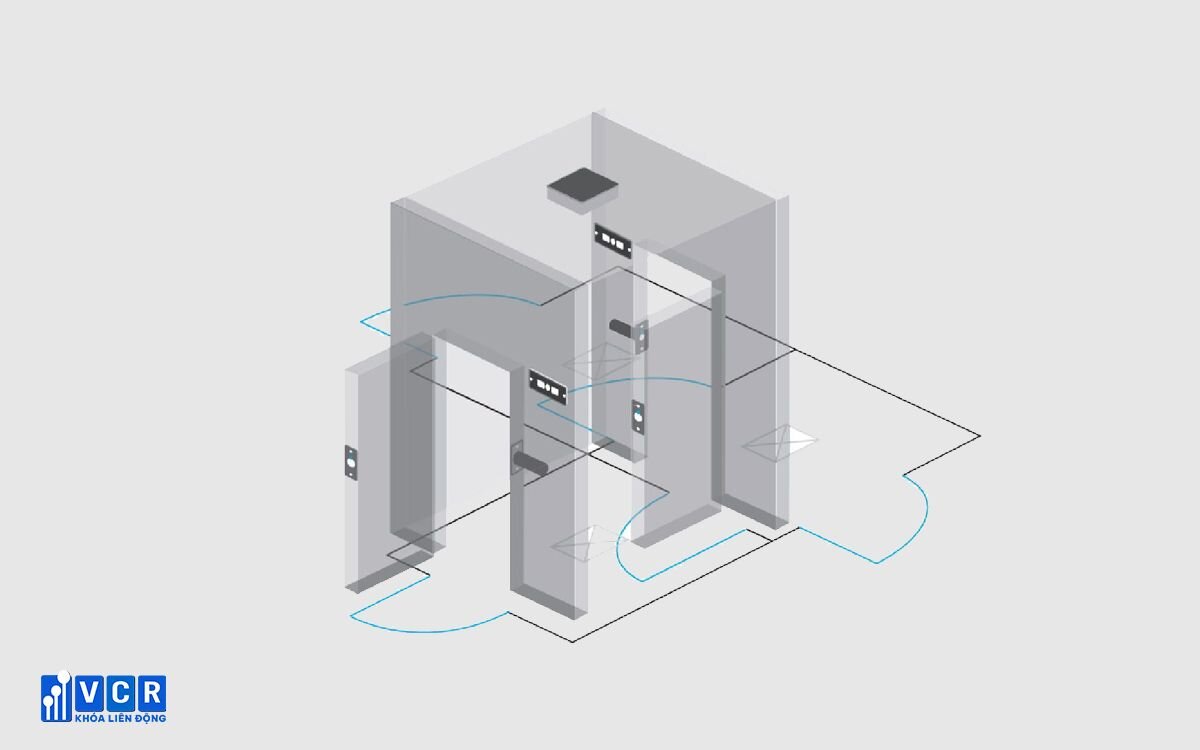

A 2-door interlock system is an electronic device that synchronizes the opening and closing of two doors within an airlock. This synchronization prevents both doors from being open simultaneously, effectively minimizing the risk of cross-contamination.

This is particularly critical in cleanrooms, where strict control over airborne particles and contaminants is essential. By maintaining a differential pressure between the cleanroom and the outside environment, the interlock system safeguards the integrity of the controlled environment.

II. System Components of 2-door Interlock

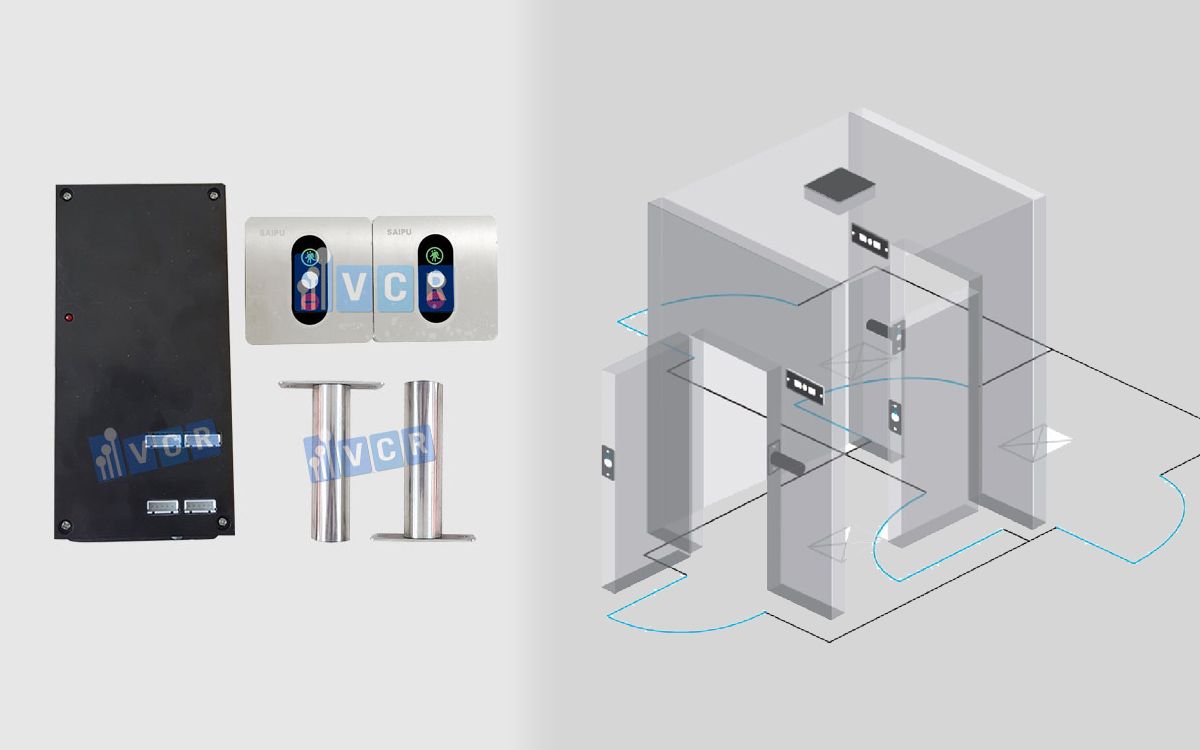

A typical 2-door interlock system comprises the following key components:

Control Box:

- Constructed from durable stainless steel for optimal corrosion resistance.

- Houses the electronic components that govern the system's operation.

- Provides inputs for connecting LED panels and electromagnetic locks.

See more: Clean Room Interlock System User Manual

Electromagnetic Locks:

- Fabricated from stainless steel for strength and reliability.

- Utilize electromagnetism to hold the doors securely shut.

- Equipped with a jack for connection to the control box.

LED Panels:

- Display visual status indicators such as door open/closed status and potential alerts.

- May include an emergency button for overriding the interlock and enabling manual door unlocking in case of emergencies.

Cables and Power Cord:

Connect the various system components and provide power to the control box.

III. Operational Principles

The core functionality of a 2-door interlock system can be summarized as follows:

- Opening one door automatically locks the other door. This is indicated by the green LED on the open door's panel and the red LED on the locked door's panel.

- A brief delay may occur after closing a door before both doors become accessible again. This delay allows for pressure stabilization within the airlock.

- If a door remains open for an extended period (typically exceeding 5 seconds), an audible alarm will sound, prompting personnel to close the door promptly.

- In case of emergencies, the emergency button on the LED panel can be pressed to unlock all doors, facilitating a safe exit from the airlock.

See more: What is Airlock in Cleanroom

IV. Applications of 2-Door Interlock Systems

Beyond cleanrooms, 2-door interlock systems find application in various settings where controlled access and contamination prevention are essential, including:

- Pass boxes: These transfer hatches utilize interlocks to ensure only one door is open at a time during material transfer, safeguarding the cleanroom environment.

- Research laboratories

- Pharmaceutical manufacturing facilities

- Food processing plants

Conclusion:

2-door interlock systems serve as a vital component in maintaining the integrity and safety of cleanrooms and other controlled environments. By understanding their functionality and components, individuals can make informed decisions regarding their selection and implementation, contributing to the overall effectiveness of contamination control measures.