Can the interlock be connected to the BMS system? This is an important question when designing a modern cleanroom. Integrating the interlock into the BMS allows for centralized monitoring of door status, instantaneous fault alerts and operational history recording, ensuring better environmental control and GMP compliance.

In the context of GMP clean factories increasingly applying automation and smart monitoring systems, the question "Can Interlock connect to BMS system?" is becoming a topic of interest to many experts and investors. Connecting the interlock system in a clean room environment with the Building Management System (BMS) not only helps synchronize door status, control air flow and ensure process safety, but also opens up the possibility of recording real data, instant warnings and retrieving operating history. This article will analyze in detail the integration capabilities, popular connection methods and practical benefits when interlock is managed from the BMS center.

1. Overview of Interlock and BMS Systems

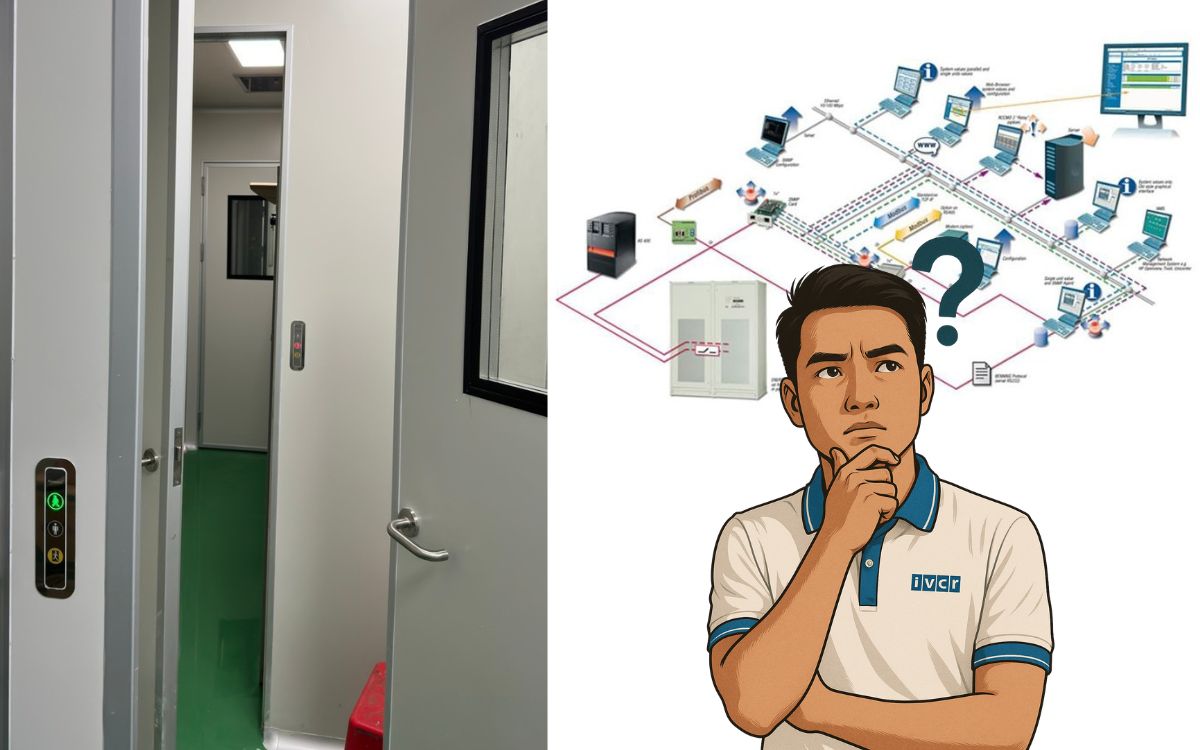

What is an Interlock? Its Role in Cleanroom Access Control

An interlock system is a door interlocking mechanism used to control access between areas that require stringent environmental control, especially in cleanrooms. Its operating principle ensures that when one door is open, the remaining doors are locked to prevent cross-contamination by air, dust, microorganisms, or other particles.

Key roles of interlock in cleanrooms:

- Maintain stable pressure conditions between different room zones.

- Prevent reverse airflow and reduce contamination risks.

- Strictly control personnel and material movement.

- Provide alerts or lock doors in case of incorrect operations.

Interlock systems are widely used in pharmaceutical, electronics, food, and cosmetics industries-where tight environmental control is essential.

What is BMS (Building Management System)? Centralized Monitoring & Control Function

A BMS (Building Management System) enables centralized monitoring and control of building equipment and systems such as air conditioning, lighting, HVAC, security, fire alarms, and auxiliary systems like interlock, AHU, HEPA fan units...

Main functions of BMS:

- Centrally manage the operational status of all equipment.

- Log real-time operating data.

- Detect faults early and automatically send alerts.

- Optimize operations, save energy, and enhance overall safety.

Why Integrate Interlock with BMS?

Connecting interlock systems to BMS offers multiple advantages over standalone operation:

- Centralized monitoring: Operators can monitor door status (open/closed), interlock states, and faults directly via the BMS interface.

- Instant alerts: The system sends immediate alerts for issues like door not closing properly or being open for too long.

- Activity traceability: All door operations are logged, supporting compliance checks with GMP procedures.

- Optimized workflow: Minimizes manual checking and enhances cleanroom control efficiency.

Integrating interlock into BMS is an essential trend in modern factories, enabling system synchronization, productivity improvement, and compliance with quality standards like GMP and ISO 14644.

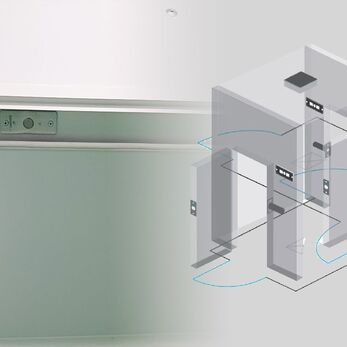

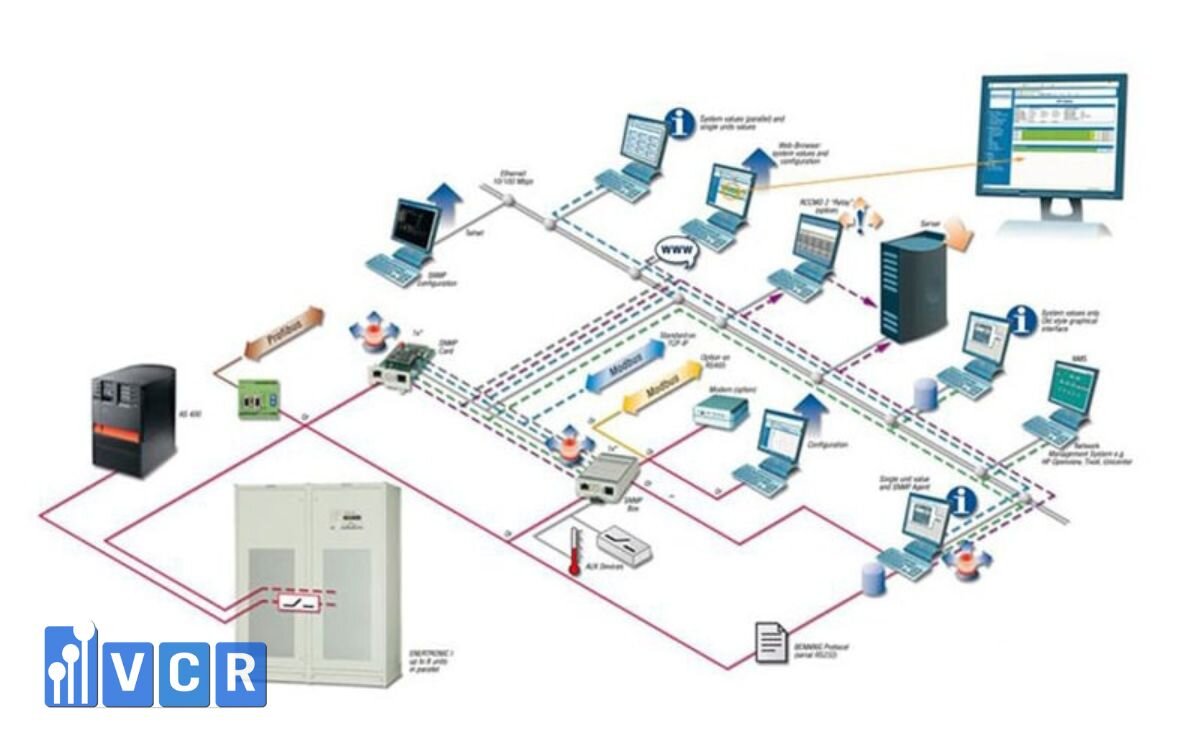

2. Methods of Connecting Interlock to BMS

Interlock systems can be integrated with BMS through various methods depending on monitoring depth, control features, and existing infrastructure. Below are the three most common methods:

1. Digital Input/Output (I/O) Connection

This is the simplest method. The interlock system sends status signals (open/close, fault, etc.) via digital input/output to the BMS.

Advantages:

- Easy installation, no programming needed.

- Suitable for small systems with basic monitoring needs.

- Low cost.

Limitations:

- Limited data transmission.

- No remote control or advanced monitoring capabilities.

- No operation history tracking.

2. Communication via RS485, Modbus RTU

This method uses Modbus RTU protocol over RS485, allowing BMS to directly communicate with compatible interlock controllers.

Advantages:

- Stable data transmission over long distances (up to hundreds of meters).

- Supports detailed status monitoring: interlock faults, delay times, individual door states.

- Multiple devices can share the same communication line.

Limitations:

- Requires technical knowledge for Modbus address setup and communication configuration.

- Slower data rate compared to TCP/IP networks.

3. Integration via TCP/IP with Central Monitoring Software

This advanced solution connects the interlock system via Ethernet (TCP/IP) and synchronizes it with SCADA/BMS software.

Advantages:

- Real-time monitoring and control of individual doors.

- Data logging, event statistics, and intelligent alerts.

- Easy system expansion and integration with other systems like HVAC, CCTV, fire alarms...

Limitations:

- Higher initial investment.

- Requires compatible monitoring software and a skilled implementation team.

Comparison Table of Connection Methods

|

Method |

Advantages |

Limitations |

|

Digital I/O |

Easy setup, low cost |

Limited monitoring functions |

|

RS485 / Modbus RTU |

Stable, easy to expand |

Requires technical configuration |

|

TCP/IP |

Comprehensive monitoring & control |

High cost, requires software and technical expertise |

See more: Provider of Interlock Locks for the Airlock Area in the Cosmetics Industry

3. Benefits of Integrating Interlock with BMS

Integrating interlock into BMS not only synchronizes system operation but also enhances safety, transparency, and convenience for the cleanroom environment. Below are the key benefits:

1. Enhanced Safety and Precise Access Control

When monitored by BMS, all access operations are controlled accurately and automatically. Conditions such as:

- Allowing only one door to open at a time,

- Blocking door access if room pressure is not met,

- Denying access during system fault states...

…can all be set and enforced via BMS software. This minimizes risks of cross-contamination, pressure imbalance, or human error.

2. Instant Fault Alerts

BMS allows real-time fault notifications to the central monitoring room in case of interlock issues such as:

- Doors not closing properly,

- Door open time exceeding limits,

- Control errors or power loss…

This enables quick technician response, avoiding production disruption or cleanroom non-compliance.

3. Operational Traceability

Every door action, access time, and user ID (if integrated with access control) is logged by the BMS. This data is critical for:

- GMP/ISO compliance auditing,

- Investigating environmental incidents,

- Training and improving staff procedures.

4. Optimized Operations and Reduced Staffing

Instead of placing personnel at each interlock, BMS enables centralized monitoring via a software interface. This helps:

- Reduce staffing needs,

- Save management costs,

- Improve system oversight-especially in facilities with multiple clean zones.

See more: Latest price list of Interlock used in food factory

4. Real-World Applications by Industry

Pharmaceutical Industry: Cleanroom Classification Control and Cross-Contamination Prevention

In pharmaceutical manufacturing, maintaining cleanroom classifications per GMP standards is mandatory. Integrating interlock systems into the BMS helps:

- Strictly control access between rooms of different cleanliness levels (e.g., from ISO 8 to ISO 7).

- Prevent simultaneous opening of multiple doors, avoiding reverse airflow and reducing cross-contamination by microorganisms or fine dust.

- Provide instant alerts for procedural errors, ensuring compliance with SOP (Standard Operating Procedures).

This is an optimal solution for controlling production environments, especially in sterile filling areas, injectable drug manufacturing, and vaccine production.

Food Industry: Cold Chain Management and Personnel Flow Control

In food factories, integrating interlocks with BMS enables effective management of areas such as cold rooms, preparation zones, and packaging rooms:

- Ensures temperature stability by limiting door open time.

- Controls personnel movement paths, preventing crossover between “clean” and “unclean” zones.

- Logs access history to support traceability during HACCP or ISO 22000 audits.

Additionally, the system can be integrated with hand sterilizers and gas sensors to only allow door opening when safety conditions are met.

Electronics Industry: Dust and Static Control During Equipment Operation

Manufacturing electronic components such as semiconductors, PCBs, or LCDs requires ultra-clean environments and strict ESD control:

- Interlocks prevent doors from opening before the air shower cycle completes.

- Control access to production areas, minimizing particle contamination.

- Interface with ESD systems to ensure personnel are de-electrified before entry.

Integrating this system into BMS allows monitoring of operational performance and early fault alerts, ensuring product quality and production efficiency.

5. Key Considerations When Connecting Interlock to BMS

Integrating interlock systems with BMS requires compatibility in communication, software, and technical teams. Here are key points to ensure smooth and effective deployment:

1. Ensure Communication Compatibility

Before implementation, verify the supported communication protocol of the interlock controller:

- Does it support digital I/O?

- Does it include RS485, Modbus RTU, or Ethernet TCP/IP ports?

Hardware and communication compatibility are the first criteria for selecting the appropriate integration method.

2. Verify Availability of Modbus or TCP/IP Protocols

If the BMS uses Modbus RTU or Modbus TCP/IP, the interlock must also support the same protocol. Incompatibility may lead to communication errors or require protocol converters, adding costs.

Also, parameters like device address, baud rate, parity bits, etc., must be uniformly configured between both systems.

3. Ensure the Monitoring Software Supports Integration

Modern interlock systems can transmit detailed data such as door status, error codes, door open times, etc. However, to display this data, the BMS or SCADA software must support:

- Accurate Modbus address mapping.

- User-friendly HMI graphics.

- Time-based data logging and retrieval.

If direct support is unavailable, custom HMI programming or OPC Server integration may be needed.

4. Deploy a Skilled Technical Team

Interlock-BMS integration involves more than physical connection. It also includes:

- Assigning device addresses.

- Configuring the BMS to read interlock signals correctly.

- Testing, commissioning, and verifying complete signal workflows.

Hence, it’s crucial to have a team knowledgeable in both automation and cleanroom systems to ensure precise and stable operation.

See more: Why is interlock a mandatory device in GMP airlock?

6. Frequently Asked Questions

Can interlock systems operate independently without BMS integration?

→ Yes, interlocks can function independently with basic door interlocking. However, connecting to a BMS allows:

- Transmitting door and fault statuses to a central monitoring room.

- Activating alerts for issues (e.g., prolonged door opening, sensor errors).

- Enabling remote monitoring and timely response by managers.

This integration enhances safety, minimizes errors, and ensures GMP compliance in critical production environments.

Can door status be monitored remotely when interlock is connected to BMS?

→ Absolutely. When integrated into BMS, operators can:

- Monitor the open/close status of each door in real-time.

- View access history, including duration and user (if paired with access control).

- Receive immediate alerts for abnormal conditions or failed interlocks.

This is especially valuable in areas requiring strict environmental control, such as sterile drug production or food packaging lines.

Which interlock models support Modbus communication?

→ Many modern interlock models from cleanroom equipment manufacturers like:

- VCR

- KOMEG

- Kanomax

- …and others

…come with built-in Modbus RTU (RS485) or Modbus TCP/IP interfaces for easy integration with BMS. Always check the technical datasheet to ensure compatibility.

7. Need Help Integrating Interlock with Your BMS?

Integrating interlocks with BMS not only enables centralized monitoring but also enhances safety, reduces operational errors, and ensures strict compliance with standards like GMP and ISO 14644.

Contact VCR - your cleanroom solutions expert for:

- On-site technical consultation

- Selection of interlock models compatible with BMS

Let me know if you'd like this compiled into a formatted document (Word or PDF) or uploaded to your website CMS.

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Diep VCR