In a cosmetics manufacturing facility, the airlock zone acts as a buffer between the outside environment and the clean‐production area. An interlock lock system helps tightly control the flow of personnel and goods, prevent cross contamination, maintain stable pressure differentials, and meet GMP standards in modern cleanroom design.

- 1. Quick Introduction to Interlock Locks in the Cosmetics Industry Airlock

- 2. Specific Requirements for Interlock Locks in Cosmetics Factories

- 3. Benefits of Using a Proper-Standard Interlock Lock

- 4. Criteria for Selecting a Reliable Interlock Lock Provider for Cosmetics Factories

- 5. VCR – A Reliable Provider of Interlock Locks for Cosmetics Factories

- 6. Why Choose VCR Instead of Other Providers?

- FAQ

1. Quick Introduction to Interlock Locks in the Cosmetics Industry Airlock

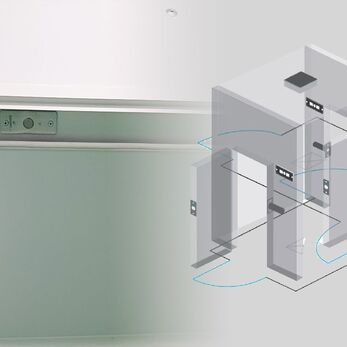

An interlock system is a safety control system that allows only one door to open at a time within an airlock area. When one door is open, the other doors are locked to prevent uncontrolled movement of air and dust between areas of different cleanliness levels. In cosmetics factories, the airlock serves as the transition zone between the external environment and the clean production areas. Given that the cosmetics industry uses many volatile raw materials which can cause cross-contamination, controlling the movement of people and goods is mandatory.

Interlock locks help ensure:

-

Prevention of cross contamination: limiting dust, microorganisms and suspended particles from migrating from lower-cleanliness zones to higher-cleanliness zones.

-

Maintaining cleanroom pressure: preserving the pressure differentials between rooms, ensuring air only moves from cleaner to less clean areas.

-

Adherence to GMP standards: regulations such as ISO 22716 and ASEAN-GMP clearly require physical flow control mechanisms like interlock systems.

With increasingly strict requirements in cosmetics manufacturing - especially for makeup, skincare or bio-active ingredient products - interlock systems are no longer optional but have become mandatory in cleanroom design.

Read more: Latest price list of Interlock used in Cosmetic factory

2. Specific Requirements for Interlock Locks in Cosmetics Factories

Compliance with ISO 22716 and ASEAN-GMP

In the cosmetics sector, the ISO 22716 standard and ASEAN–GMP guidelines form the mandatory basis for ensuring product quality and safety. Therefore the interlock system used in the airlock zone must:

-

Be designed to effectively control cross-flows.

-

Support one-way management of personnel and goods.

-

Have clear technical documentation and origin information to serve GMP assessment.

Choosing non-compliant equipment may directly impact the ability to maintain cleanroom conditions and create risk during factory validation.

Suitable for Cleanroom Class 100,000 (ISO 8)

The airlock area in cosmetics factories is often at cleanliness level Class 100,000 (according to ISO 14644-1). Thus, devices such as interlock locks must:

-

Not generate dust or cause vibration during operation.

-

Feature smooth surfaces, easy to clean, and resist dust accumulation.

-

Have enclosure materials, wiring, and accessories compatible with controlled environments.

Additionally, the design should consider the possibility of wall-flush installation, space optimisation and avoidance of gaps that trap dust.

Resistance to chemicals from products and solvents

In a cosmetics production environment, exposure to chemicals like ethanol, fragrance, preservatives is unavoidable. The interlock system must ensure:

-

Enclosure made of stainless steel 304 or engineering plastic that resists corrosion.

-

Components such as push-buttons and sensors that are not affected by solvent vapours.

-

Long service life under high humidity and chemical exposure.

Chemical resistance not only increases equipment lifespan but also contributes to long-term maintenance of cleanroom conditions.

Intuitive interface for non-technical staff

A characteristic of the cosmetics industry is that operating staff are often not deeply technical. Therefore interlock locks need to be designed for ease of use:

-

Clear LED indicators to easily observe door status.

-

Push-buttons with simple, easily understandable symbols.

-

Intelligent lock/unlock mechanisms, automatic reset when the door closes.

A system that is easy to use helps reduce operation errors, shorten training time and improve cleanroom control efficiency.

Read more: Why is interlock a mandatory device in GMP airlock?

3. Benefits of Using a Proper-Standard Interlock Lock

Prevents cross contamination between zones (production, packaging, storage)

In cosmetics factories, maintaining cleanliness in each zone is key to ensuring product quality and GMP compliance. The interlock system controls the movement of personnel and materials, allowing only one door to open at any time in the airlock. As a result, the risk of dust, microorganisms or impurities migrating from one zone to another is minimised.

Especially during production and packaging - where the risk of cross contamination from raw materials, fragrances or solvents is high - the interlock system serves as an effective “behavioural filter”.

Maintains pressure differential between airlock rooms

The interlock lock is not just a mechanical solution but plays an important role in maintaining the pressure differentials between cleanrooms. In a GMP-standard cosmetics factory, zones with higher cleanliness must maintain positive pressure to push air toward zones of lower cleanliness.

Controlling door opening via an interlock avoids sudden “pressure drops” caused by two doors opening simultaneously, thereby preserving the ideal environment for each functional zone.

Enhances safety and elevates the factory’s professional image

Beyond technical objectives, the interlock system contributes to elevating the operation of the factory. Automatic locking/unlocking in sequence, LED status indicators and alarms on incorrect operations help reduce human errors, prevent accidents caused by door impact or slips when doors open unexpectedly.

Additionally, an airlock system fully equipped with interlock locks creates a professional impression when customers, partners or auditors visit for inspection.

Easy inspection and traceability (if integrated with monitoring system)

For factories applying industry 4.0 technology, the interlock lock system can be integrated with features to record operational status (data logs), enabling retrieval of door open/close history, detection of operation errors or identification of root-causes of incidents.

This capability is especially useful during internal audits, GMP inspections or traceability when defected products are detected - thereby enhancing the factory’s end-to-end quality control.

Read more: Prepping for Success: Essential Considerations Before Cleanroom Door Interlock Installation

4. Criteria for Selecting a Reliable Interlock Lock Provider for Cosmetics Factories

Choosing the right interlock lock provider not only affects the operation efficiency of the airlock zone, but also directly relates to the ability to meet GMP standards in the cosmetics industry. Below are important criteria to consider:

Industry experience in cosmetics manufacturing

Not all interlock lock providers understand the specific needs of the cosmetics industry such as:

-

One-way movement control of personnel/materials (clean/dirty).

-

Cross-control between mix-room → filling → packaging zones.

-

Device optimisation in the constrained cleanroom space.

A provider with practical experience in cosmetics factories will propose pragmatic solutions rather than just supplying equipment.

Customised solution according to factory layout

Each cosmetics factory has a different layout with distinct airlock counts, door positions and pressure differences. A reliable provider should:

-

Be able to design interlock lock systems according to the actual floor plan.

-

Provide multiple connection options (with/without power, with/without LCD display…).

-

Support solution adjustments during the construction process.

Provide drawings, installation and operation guides

Even the most modern interlock system will not be effective if it is not installed correctly. A competent supplier will:

-

Supply detailed wiring diagram drawings.

-

Provide clear documentation in Vietnamese.

-

Support training for technicians and QC staff.

This helps minimise installation errors and ensures the equipment operates stably from day one.

Fast after-sales service and availability of spare parts

In a continuous production environment like the cosmetics industry, downtime due to equipment failure can cause significant losses. Therefore the provider must commit to:

-

Clear warranty terms and quick response time.

-

Availability of replacement parts to avoid repair delays.

-

Remote or onsite technical support when needed.

Provide documentation of origin, technical standards

This is a key factor to help the factory pass GMP audits and demonstrate equipment reliability to partners. Documentation should include:

-

CO (Certificate of Origin), CQ (Certificate of Quality).

-

Catalogues, product datasheets, schematic diagrams.

-

Certifications of electricity, EMC, safety if required.

Read more: Mechanical interlock vs electronic interlock: which device is more GMP compliant?

5. VCR – A Reliable Provider of Interlock Locks for Cosmetics Factories

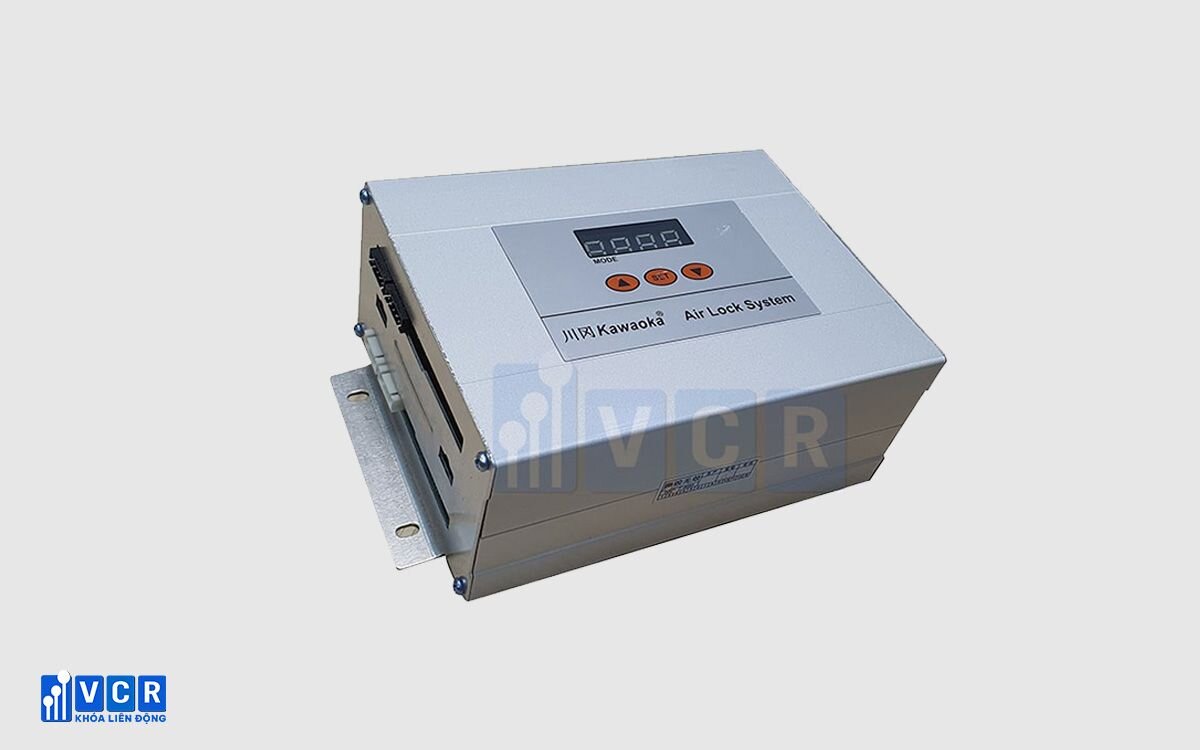

With over 10 years of experience supplying cleanroom equipment in industries such as pharmaceuticals, cosmetics, food and electronics, VCR deeply understands the unique requirements of each sector - especially the cosmetics industry, where hygiene and cross-control are top priority.

The interlock lock system provided by VCR not only meets GMP-ISO 22716 standards, but also optimises investment cost and is easy for enterprises to operate.

Outstanding advantages of VCR’s interlock locks

-

Stable operation, long lifespan: anti-electromagnetic-interference design, ensuring no signal errors in environments with many electrical devices.

-

Easy installation: modular system, suitable for both new projects and renovations of existing factories.

-

Customisable: can connect multiple doors (from 2 to 6 doors), integrate sensors, LED indicators, access control.

-

Long warranty: up to 18 months warranty and support for genuine spare parts.

Supports on-site survey and layout consultation.

VCR does not just sell products - they provide comprehensive solutions:

-

On-site survey at the factory, assessment of the actual airlock space.

-

Create interlock connection diagram suitable for the flow of personnel and materials.

-

Consult layout for device placement to ensure one-way process, avoid cross-contamination.

-

Provide technical drawings, detailed installation instructions, and remote support throughout installation.

Read more: Supplier of GMP standard clean room door interlocks

6. Why Choose VCR Instead of Other Providers?

When selecting interlock locks for the airlock area in a cosmetics factory, choosing the right provider not only affects operational efficiency but also determines the level of GMP compliance of the factory. Below is a detailed comparison table between VCR and other common providers in the market:

| Criteria | VCR | Other providers |

|---|---|---|

| Experience in cosmetics | Has real-world experience with many cosmetics factory projects and understands the specific requirements of each sub-area. | Mainly focuses on electronics or medical sectors, lacks deep understanding of cosmetics GMP. |

| Customisation by design | Provides flexible interlock system design tailored to the actual factory layout. | Offers standard models, hard to adjust when interior design changes. |

| Documentation of technical | Supplies full CO, CQ, datasheet and catalog; ready for GMP/ISO audit. | May lack documents or provide outdated versions, not audit-ready. |

| Technical support | Provides on-site survey, installation and direct operational guidance. | Offers phone/email remote support, slow response to real-world breakdowns. |

With advantages in industry experience, customisation capability, full documentation and on-site support service, VCR is a trustworthy partner for cosmetics companies building or upgrading cleanroom systems to international standards.

Read more: Clean Room Interlock System User Manual: Maintaining a Sterile Environment

FAQ

Q1. Does an interlock lock need periodic maintenance?

Yes. An interlock lock is an electro-mechanical device that must maintain stable operation in a cleanroom environment. To ensure longevity and avoid disruptions in the airlock process, users should:

-

Perform inspections every 6–12 months depending on usage and environment.

-

Clean surface contacts, check wiring and electrical contacts.

-

Inspect the locking/unlocking mechanism and signal indicators.

-

Replace worn components as recommended by the provider.

VCR offers on-site interlock system maintenance and inspection services, so customers can operate continuously with peace of mind.

Q2. Does VCR support system design consultation for interlock locks?

Yes. VCR is not just a product supplier; they accompany customers from design through installation:

-

On-site factory survey, capturing airlock layout and operating process.

-

Propose interlock lock placement solution matching door count, opening direction and pressure requirements.

-

Develop technical schematic, specify module types and required accessories.

-

Ensure the entire system meets cosmetics industry GMP standards.

Design consultation is completely free when customers purchase devices from VCR.

Q3. What is the delivery time for interlock locks?

Typically, delivery is within 3–7 working days from order confirmation.

-

For standard models available in stock: delivery within 2–3 days.

-

For customised design or expanded systems: delivery from 5–7 days.

VCR commits to on-time delivery and supports direct delivery to the factory if required.

Q4. Can interlock locks be integrated with access control systems?

Absolutely. VCR provides solution integration of interlock locks with access control systems such as:

-

RFID card, PIN code, fingerprint.

-

Centralised attendance system, access control.

-

Connection to monitoring software and access log storage.

This integration helps factories elevate control level, prevent unauthorised access and meet quality control requirements in cosmetics production.

Selecting the right interlock lock for the airlock area not only helps ensure your production process is GMP-compliant, but also improves operational efficiency and the professional image of your factory.

With many years of experience in the cosmetics cleanroom sector, VCR commits to:

-

Designing optimal interlock system according to your factory layout.

-

Providing official equipment with full CO, CQ certification.

-

Supporting installation – maintenance – full access control integration.

-

Rapid delivery, competitive pricing, clear warranty terms.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Dat VCR