Interlocks are door control systems that allow only one door to open at a time, preventing uncontrolled airflow and movement of people. In hospitals, interlocks help maintain pressure, prevent cross-contamination, and are an important element of standard airlock design.

- 1. What is an Interlock? Why is it important in hospital airlocks?

- 2. Mandatory requirements for hospital airlock design

- 3. Choosing the right interlock system for hospitals

- 4. Technical Considerations When Installing Interlocks in Hospitals

- 5. Hospital Airlock Design Checklist

- 6. Frequently Asked Questions

- 7. Need Assistance Choosing a Hospital Interlock System? Contact VCR

In the design of medical cleanrooms, the requirements for hospital airlock design are key to ensuring airflow control, preventing cross-contamination, and maintaining safe pressure between critical areas such as operating rooms, isolation areas, or drug preparation rooms. The airlock system not only needs to integrate interlocks to ensure only one door is open at a time, but also must meet technical requirements such as differential pressure, door status sensors, and strict operating procedures. When designed properly, airlocks help optimize HVAC system efficiency, comply with microbiological control and medical safety regulations. This article will analyze in detail the important criteria you need to know - from interlock type selection, door layout, to pressure control - to support the construction of a standard, safe, and effective hospital airlock.

1. What is an Interlock? Why is it important in hospital airlocks?

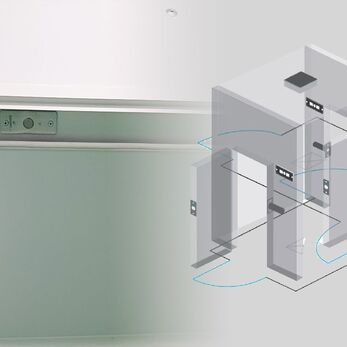

An interlock, also known as a door interlocking system, is a control mechanism that ensures only one door within a designated system can be opened at any given time. When one door is open, all other doors in the same system are automatically locked to prevent uncontrolled airflow or unauthorized movement.

In healthcare environments-especially in clean zones with strict microbial control such as operating theaters, negative pressure isolation rooms, or cytotoxic drug preparation areas-interlocks play a vital role in:

- Preventing cross-contamination between areas with different cleanliness levels

- Maintaining stable pressure differentials between rooms to avoid clean air or hazardous gas leakage

- Controlling the movement of personnel, patients, and medical materials in a unidirectional workflow

Integrated with systems such as door status alarms, signal lights, and access control, interlocks are not merely auxiliary devices but essential components in modern hospital airlock design.

Practical examples:

- In a negative pressure isolation room, the interlock prevents pathogen-laden air from escaping during personnel entry or exit.

- In a sterile operating room, it prevents dust and microbes from entering from adjacent corridors.

2. Mandatory requirements for hospital airlock design

An airlock in a hospital is not just a buffer space between two rooms-it is a critical component in the infection control chain and clean airflow management. To ensure optimal performance, airlock systems must meet several stringent technical requirements:

Compliance with contamination control standards

Several standards apply to airlock design in healthcare settings, including:

- ISO 14644 - International standard for cleanroom classification and design

- HTM 03-01 - UK technical guidance on ventilation systems in healthcare

- Vietnamese hospital infection control standards (Ministry of Health)

These standards require airlocks to:

- Maintain appropriate pressure differentials (typically ±5 to ±15 Pa)

- Minimize microbial cross-contamination between clean and non-clean areas

- Operate continuously and reliably

Number of interlocked doors: 2 or 3 depending on control level

- 2-door airlock: Used in standard transitions such as corridor to prep room or lower-class cleanrooms

- 3-door airlock: Required in critical areas such as operating rooms, ICUs, or negative pressure isolation rooms to ensure one-way movement and maximum contamination control

Each door must operate independently while being centrally controlled to prevent simultaneous opening and uncontrolled airflow mixing.

Appropriate door open/close timing and delay settings

- Standard interlock delay: 3-5 seconds between door operations

- Doors should open quickly but close smoothly and firmly to avoid pressure shock

- In negative pressure rooms or toxic substance airlocks, longer delays are needed to prevent gas leakage

Integration of indicators and door status sensors

A modern interlock system for hospital airlocks should include:

- Indicator lights showing door open/close status

- Audible alarms for improper sequencing or doors left ajar

- Door status sensors (reed switch, magnetic sensors) for accurate feedback

- Central control panels for monitoring door status and troubleshooting

See more: Why is interlock a mandatory device in GMP airlock?

3. Choosing the right interlock system for hospitals

Not all interlock systems are suitable for healthcare environments. Depending on the area (e.g., operating rooms, isolation wards, drug preparation zones), investors must choose high-reliability interlocks that offer precise control and easy integration with access management systems.

Comparison of three common interlock types

|

Interlock Type |

Description & Application |

Advantages |

Limitations |

|

Mechanical |

Uses physical linkages (hinges) |

No power needed, simple, low cost |

Inflexible, prone to physical wear |

|

Basic Electronic |

Controlled via relays or timers |

Easy to install, budget-friendly |

No remote monitoring or advanced control |

|

Smart Electronic |

Integrated with sensors and control systems |

Real-time monitoring, remote control, BMS-compatible |

Higher cost, requires periodic maintenance |

For modern hospitals, smart electronic interlocks are the preferred option due to their ability to:

- Monitor door status in real time

- Auto-lock in the event of a system error

- Integrate with Building Management Systems (BMS) or Access Control platforms

Advantages of 3-door interlocks in pressure-controlled rooms

In critical areas like infectious disease isolation rooms (negative pressure) or cytotoxic drug preparation rooms (positive pressure), 3-door interlocks offer superior containment performance:

- Create a stable air buffer zone that prevents contaminants from spreading in or out

- Maintain proper pressure differentials even with frequent access

- Support unidirectional movement, critical for infection control compliance

This configuration is mandatory in cleanroom designs compliant with HTM 03-01, ISO 14644, or CDC Guidelines.

4. Technical Considerations When Installing Interlocks in Hospitals

Installing an interlock system involves more than just selecting the right device. To ensure stable operation, compatibility, and effectiveness in medical environments, several technical aspects must be considered:

Selecting the Right Installation Location

Interlocks are typically installed in airlock zones-buffer areas between spaces with differing cleanliness levels. Key locations in hospitals include:

- Corridor to operating room: to prevent cross-contamination from general zones

- Drug compounding area to microbiological control zone: to contain hazardous substances

- Negative pressure isolation room to main corridor: to stop pathogen-laden air from escaping

Note: Interlocks should be installed away from primary work areas to avoid air turbulence caused by frequent door operations.

Compatibility With Cleanroom Doors and Specialized Materials

Different door types in hospitals have specific structural features that influence the interlock configuration:

|

Cleanroom Door Type |

Interlock Installation Consideration |

|

Panel door |

Easy to surface-mount, supports concealed or exposed wiring |

|

Aluminum glass door |

Requires surface-mounted magnetic sensors or switches |

|

Lead-lined door |

Needs EMI-resistant interlocks, radiation-proof materials |

|

Automatic sliding door |

Requires careful programming to avoid unintended openings |

For optimal performance, electromagnetic locks or specialized door latches are recommended for durability and reliable interlocking.

Integration With Access Control Systems

In high-security zones-such as isolation rooms, cytotoxic storage, or surgical prep areas-integrating the interlock with access control is essential.

Common methods include:

- RFID cards

- Fingerprint scanners

- Medical-grade facial recognition

- Integration with Building Management Systems (BMS) or central fire alarms

Benefits of integration:

- Role-based and shift-based access control

- Entry/exit history logs for incident tracking

- Scheduled or emergency automatic unlocking

See more: Why Cleanrooms Depend on Door Interlock Systems: Maintaining Airtight Integrity

5. Hospital Airlock Design Checklist

To ensure a hospital airlock functions effectively and meets infection control standards (GMP, ISO 14644, HTM 03-01), the following criteria must be fulfilled:

|

Item |

Minimum Technical Requirement |

|

Number of doors |

2-3 interlocked doors, ensuring only one can open at a time to prevent airflow crossover |

|

Lock type |

Smart electronic locks with integrated door status sensors for accurate control |

|

Operating mode |

Fully automated with visual indicators (open/close) and audible alerts for incorrect sequences |

|

System expandability |

Compatible with Building Management Systems (BMS) and Access Control |

|

Construction material |

Anti-microbial, durable, and easy-to-clean materials, suitable for cleanroom environments |

Additional Recommendations:

- Include pressure differential sensors in negative pressure airlocks

- Allow adjustable delay time in buffer zones between isolation areas

- Install control panels outside clean zones for ease of monitoring and maintenance

6. Frequently Asked Questions

1. Can mechanical interlocks be used in hospital airlocks?

In principle, mechanical interlocks do not require electricity and are cost-effective. However, they lack precision, flexibility, and monitoring capabilities.

They are only suitable for non-critical support areas without pressure control requirements.

For pressure-controlled zones like isolation or surgery rooms, electronic or smart interlocks are mandatory.

2. How many doors are required in a hospital airlock?

The number of doors depends on the design and hygiene requirements:

- 2-door interlock: Used in standard transition areas

- 3-door interlock: Required in operating rooms, sterile zones, and pharmaceutical areas for one-way movement and complete air containment

Designs should comply with GMP, HTM, or CDC infection control guidelines and follow the actual floor layout.

3. Can interlocks be integrated with access control systems?

Yes. Most modern interlock systems are designed to integrate seamlessly with access control, including:

- RFID cards

- Fingerprint or facial recognition

- Access control software

- Direct connection to BMS or fire alarm systems

Integration enhances security, restricts unauthorized access, and ensures only authorized personnel can operate the doors.

7. Need Assistance Choosing a Hospital Interlock System? Contact VCR

Selecting and installing interlocks for hospital airlocks requires deep understanding of cleanroom standards, airflow control, and system integration. Minor mistakes can lead to major risks in contamination control.

Our engineering team at VCR is ready to help you:

- Recommend tailored interlock solutions for each hospital function

- Support airlock layout design that meets GMP and HTM standards

- Supply certified equipment with long-term technical maintenance

Get in touch for a free technical consultation:

VCR - Your trusted partner for cleanroom technology in healthcare and hospital infrastructure.

Hotline: 090.123.9008

Email: [email protected]

Website: https://khoaliendong.com/

Diep VCR